Page 165 - Sami Franssila Introduction to Microfabrication

P. 165

144 Introduction to Microfabrication

Oxygen

Hydrogen

Nitrogen

Burn

box DCE/HCl

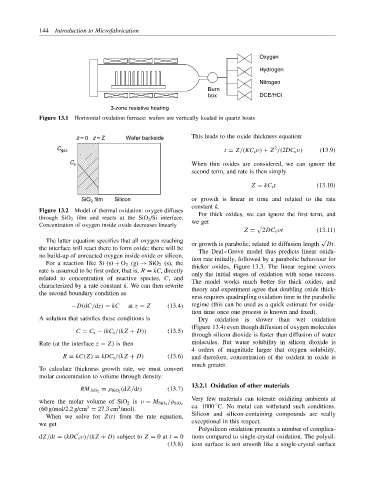

3-zone resistive heating

Figure 13.1 Horizontal oxidation furnace: wafers are vertically loaded in quartz boats

z = 0 z = Z Wafer backside This leads to the oxide thickness equation:

C gas t = Z/(KC s υ) + Z /(2DC s υ) (13.9)

2

C s When thin oxides are considered, we can ignore the

second term, and rate is then simply

Z = kC s t (13.10)

SiO film Silicon or growth is linear in time and related to the rate

2

constant k.

Figure 13.2 Model of thermal oxidation: oxygen diffuses

through SiO 2 film and reacts at the SiO 2 /Si interface. For thick oxides, we can ignore the first term, and

Concentration of oxygen inside oxide decreases linearly we get

Z = 2DC s υt (13.11)

The latter equation specifies that all oxygen reaching or growth is parabolic, related to diffusion length √ Dt.

the interface will react there to form oxide: there will be The Deal–Grove model thus predicts linear oxida-

no build-up of unreacted oxygen inside oxide or silicon. tion rate initially, followed by a parabolic behaviour for

For a reaction like Si (s) + O 2 (g) → SiO 2 (s), the thicker oxides, Figure 13.3. The linear regime covers

rate is assumed to be first order, that is, R = kC, directly only the initial stages of oxidation with some success.

related to concentration of reactive species, C, and

The model works much better for thick oxides, and

characterized by a rate constant k. We can then rewrite

theory and experiment agree that doubling oxide thick-

the second boundary condition as

ness requires quadrupling oxidation time in the parabolic

−D(dC/dz) = kC at z = Z (13.4) regime (this can be used as a quick estimate for oxida-

tion time once one process is known and fixed).

A solution that satisfies these conditions is Dry oxidation is slower than wet oxidation

(Figure 13.4) even though diffusion of oxygen molecules

C = C s − (kC s /(kZ + D)) (13.5)

through silicon dioxide is faster than diffusion of water

Rate (at the interface z = Z) is then molecules. But water solubility in silicon dioxide is

4 orders of magnitude larger that oxygen solubility,

R = kC(Z) = kDC s /(kZ + D) (13.6) and therefore, concentration of the oxidant in oxide is

much greater.

To calculate thickness growth rate, we must convert

molar concentration to volume through density:

13.2.1 Oxidation of other materials

(dZ/dt) (13.7)

RM SiO 2 = ρ SiO 2

Very few materials can tolerate oxidizing ambients at

where the molar volume of SiO 2 is υ = M SiO 2 /ρ SiO 2 ◦

3

3

(60 g/mol/2.2 g/cm = 27.3 cm /mol). ca. 1000 C. No metal can withstand such conditions.

When we solve for Z(t) from the rate equation, Silicon and silicon-containing compounds are really

we get exceptional in this respect.

Polysilicon oxidation presents a number of complica-

dZ/dt = (kDC s υ)/(kZ + D) subject to Z = 0 at t = 0 tions compared to single-crystal oxidation. The polysil-

(13.8) icon surface is not smooth like a single-crystal surface