Page 250 - Sami Franssila Introduction to Microfabrication

P. 250

Structures by Deposition 229

(a) (b)

Figure 23.6 Lift-off process (a) metal deposition on resist pattern and (b) resist dissolution and metal lift-off

(a) (b)

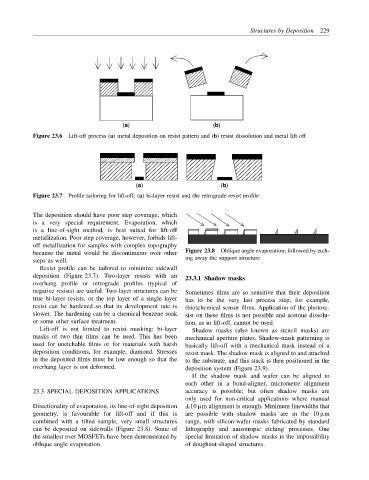

Figure 23.7 Profile tailoring for lift-off: (a) bi-layer resist and (b) retrograde resist profile

The deposition should have poor step coverage, which

is a very special requirement. Evaporation, which

is a line-of-sight method, is best suited for lift-off

metallization. Poor step coverage, however, forbids lift-

off metallization for samples with complex topography

because the metal would be discontinuous over other Figure 23.8 Oblique angle evaporation; followed by etch-

steps as well. ing away the support structure

Resist profile can be tailored to minimize sidewall

deposition (Figure 23.7). Two-layer resists with an 23.3.1 Shadow masks

overhang profile or retrograde profiles (typical of

negative resists) are useful. Two-layer structures can be Sometimes films are so sensitive that their deposition

true bi-layer resists, or the top layer of a single layer has to be the very last process step, for example,

resist can be hardened so that its development rate is (bio)chemical sensor films. Application of the photore-

slower. The hardening can be a chemical benzene soak sist on these films is not possible and acetone dissolu-

or some other surface treatment. tion, as in lift-off, cannot be used.

Lift-off is not limited to resist masking: bi-layer Shadow masks (also known as stencil masks) are

masks of two thin films can be used. This has been mechanical aperture plates. Shadow-mask patterning is

used for unetchable films or for materials with harsh basically lift-off with a mechanical mask instead of a

deposition conditions, for example, diamond. Stresses resist mask. The shadow mask is aligned to and attached

in the deposited films must be low enough so that the to the substrate, and this stack is then positioned in the

overhang layer is not deformed. deposition system (Figure 23.9).

If the shadow mask and wafer can be aligned to

each other in a bond-aligner, micrometre alignment

23.3 SPECIAL DEPOSITION APPLICATIONS accuracy is possible; but often shadow masks are

only used for non-critical applications where manual

Directionality of evaporation, its line-of-sight deposition ±10 µm alignment is enough. Minimum linewidths that

geometry, is favourable for lift-off and if this is are possible with shadow masks are in the 10 µm

combined with a tilted sample, very small structures range, with silicon-wafer masks fabricated by standard

can be deposited on sidewalls (Figure 23.8). Some of lithography and anisotropic etching processes. One

the smallest ever MOSFETs have been demonstrated by special limitation of shadow masks is the impossibility

oblique angle evaporation. of doughnut-shaped structures.