Page 359 - Sami Franssila Introduction to Microfabrication

P. 359

338 Introduction to Microfabrication

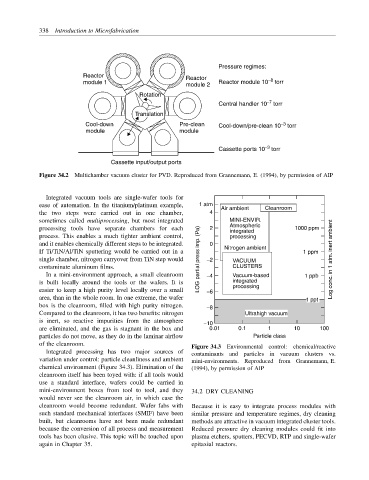

Pressure regimes:

Reactor Reactor

−8

module 1 module 2 Reactor module 10 torr

Rotation

−7

Central handler 10 torr

Translation

Cool-down Pre-clean Cool-down/pre-clean 10 torr

−3

module module

−3

Cassette ports 10 torr

Cassette input/output ports

Figure 34.2 Multichamber vacuum cluster for PVD. Reproduced from Grannemann, E. (1994), by permission of AIP

Integrated vacuum tools are single-wafer tools for

ease of automation. In the titanium/platinum example, 1 atm Air ambient Cleanroom

the two steps were carried out in one chamber, 4

sometimes called multiprocessing, but most integrated MINI-ENVIR.

processing tools have separate chambers for each 2 Atmospheric 1000 ppm

integrated

process. This enables a much tighter ambient control, processing

and it enables chemically different steps to be integrated. 0 Nitrogen ambient

If Ti/TiN/Al/TiN sputtering would be carried out in a 1 ppm

single chamber, nitrogen carryover from TiN step would LOG partial press imp. (Pa) −2 VACUUM Log conc. in 1 atm. inert ambient

contaminate aluminum films. CLUSTERS

In a mini-environment approach, a small cleanroom −4 Vacuum-based 1 ppb

is built locally around the tools or the wafers. It is integrated

processing

easier to keep a high purity level locally over a small −6

area, than in the whole room. In one extreme, the wafer 1 ppt

box is the cleanroom, filled with high purity nitrogen. −8

Compared to the cleanroom, it has two benefits: nitrogen Ultrahigh vacuum

is inert, so reactive impurities from the atmosphere −10

are eliminated, and the gas is stagnant in the box and 0.01 0.1 1 10 100

particles do not move, as they do in the laminar airflow Particle class

of the cleanroom. Figure 34.3 Environmental control: chemical/reactive

Integrated processing has two major sources of contaminants and particles in vacuum clusters vs.

variation under control: particle cleanliness and ambient mini-environments. Reproduced from Grannemann, E.

chemical environment (Figure 34.3). Elimination of the (1994), by permission of AIP

cleanroom itself has been toyed with: if all tools would

use a standard interface, wafers could be carried in

mini-environment boxes from tool to tool, and they 34.2 DRY CLEANING

would never see the cleanroom air, in which case the

cleanroom would become redundant. Wafer fabs with Because it is easy to integrate process modules with

such standard mechanical interfaces (SMIF) have been similar pressure and temperature regimes, dry cleaning

built, but cleanrooms have not been made redundant methods are attractive in vacuum integrated cluster tools.

because the conversion of all process and measurement Reduced pressure dry cleaning modules could fit into

tools has been elusive. This topic will be touched upon plasma etchers, sputters, PECVD, RTP and single-wafer

again in Chapter 35. epitaxial reactors.