Page 358 - Sami Franssila Introduction to Microfabrication

P. 358

34

Integrated Processing

Integrated processing involves the chaining of pro- of integrated processing: the titanium surface is kept

cess steps into longer sequences. Process integration clean under vacuum, and platinum, which is deposited

is also about chaining process steps into sequences immediately after titanium, adheres to it well, whereas

but in a different sense: process integration is device- platinum would not adhere to an oxidized titanium sur-

related, whereas integrated processing is a tool-view of face, which would result immediately if a titanium wafer

step chaining. was transferred from one deposition system to another.

Integrated processing has both scientific and manufac-

turing benefits. It enables a much higher degree of con-

34.1 AMBIENT CONTROL trol over materials, interfaces and surfaces. This helps us

to understand what is really going on in our processes.

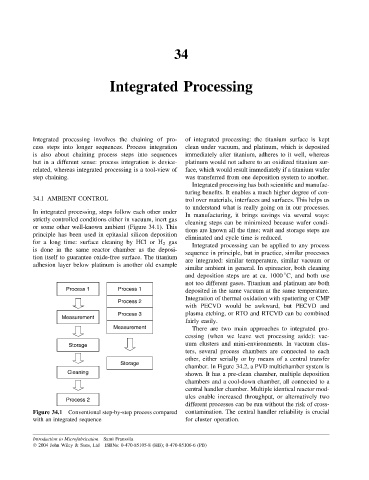

In integrated processing, steps follow each other under In manufacturing, it brings savings via several ways:

strictly controlled conditions either in vacuum, inert gas cleaning steps can be minimized because wafer condi-

or some other well-known ambient (Figure 34.1). This tions are known all the time; wait and storage steps are

principle has been used in epitaxial silicon deposition eliminated and cycle time is reduced.

for a long time: surface cleaning by HCl or H 2 gas Integrated processing can be applied to any process

is done in the same reactor chamber as the deposi- sequence in principle, but in practice, similar processes

tion itself to guarantee oxide-free surface. The titanium are integrated: similar temperature, similar vacuum or

adhesion layer below platinum is another old example

similar ambient in general. In epireactor, both cleaning

and deposition steps are at ca. 1000 C, and both use

◦

not too different gases. Titanium and platinum are both

Process 1 Process 1 deposited in the same vacuum at the same temperature.

Integration of thermal oxidation with sputtering or CMP

Process 2

with PECVD would be awkward, but PECVD and

Process 3 plasma etching, or RTO and RTCVD can be combined

Measurement

fairly easily.

Measurement There are two main approaches to integrated pro-

cessing (when we leave wet processing aside): vac-

Storage uum clusters and mini-environments. In vacuum clus-

ters, several process chambers are connected to each

other, either serially or by means of a central transfer

Storage

chamber. In Figure 34.2, a PVD multichamber system is

Cleaning shown. It has a pre-clean chamber, multiple deposition

chambers and a cool-down chamber, all connected to a

central handler chamber. Multiple identical reactor mod-

Process 2 ules enable increased throughput, or alternatively two

different processes can be run without the risk of cross-

Figure 34.1 Conventional step-by-step process compared contamination. The central handler reliability is crucial

with an integrated sequence for cluster operation.

Introduction to Microfabrication Sami Franssila

2004 John Wiley & Sons, Ltd ISBNs: 0-470-85105-8 (HB); 0-470-85106-6 (PB)