Page 353 - Sami Franssila Introduction to Microfabrication

P. 353

332 Introduction to Microfabrication

Process 3

Deposition rate 1 4

2

window

Temperature

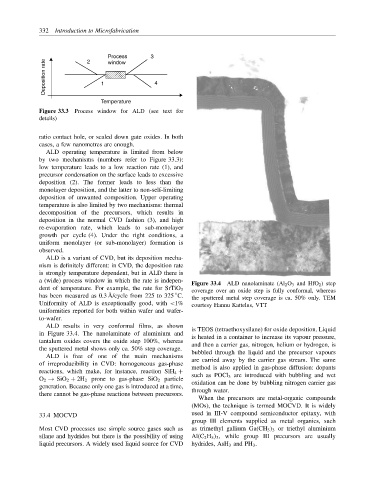

Figure 33.3 Process window for ALD (see text for

details)

ratio contact hole, or scaled down gate oxides. In both

cases, a few nanometres are enough.

ALD operating temperature is limited from below

by two mechanisms (numbers refer to Figure 33.3):

low temperature leads to a low reaction rate (1), and

precursor condensation on the surface leads to excessive

deposition (2). The former leads to less than the

monolayer deposition, and the latter to non-self-limiting

deposition of unwanted composition. Upper operating

temperature is also limited by two mechanisms: thermal

decomposition of the precursors, which results in

deposition in the normal CVD fashion (3), and high

re-evaporation rate, which leads to sub-monolayer

growth per cycle (4). Under the right conditions, a

uniform monolayer (or sub-monolayer) formation is

observed.

ALD is a variant of CVD, but its deposition mecha-

nism is definitely different: in CVD, the deposition rate

is strongly temperature dependent, but in ALD there is

a (wide) process window in which the rate is indepen-

Figure 33.4 ALD nanolaminate (Al 2 O 3 and HfO 2 ) step

dent of temperature. For example, the rate for SrTiO 3 coverage over an oxide step is fully conformal, whereas

has been measured as 0.3 ˚ A/cycle from 225 to 325 C. the sputtered metal step coverage is ca. 50% only. TEM

◦

Uniformity of ALD is exceptionally good, with <1% courtesy Hannu Kattelus, VTT

uniformities reported for both within wafer and wafer-

to-wafer.

ALD results in very conformal films, as shown is TEOS (tetraethoxysilane) for oxide deposition. Liquid

in Figure 33.4. The nanolaminate of aluminium and is heated in a container to increase its vapour pressure,

tantalum oxides covers the oxide step 100%, whereas and then a carrier gas, nitrogen, helium or hydrogen, is

the sputtered metal shows only ca. 50% step coverage. bubbled through the liquid and the precursor vapours

ALD is free of one of the main mechanisms

of irreproducibility in CVD: homogeneous gas-phase are carried away by the carrier gas stream. The same

method is also applied in gas-phase diffusion: dopants

reactions, which make, for instance, reaction SiH 4 +

such as POCl 3 are introduced with bubbling and wet

O 2 → SiO 2 + 2H 2 prone to gas-phase SiO 2 particle

oxidation can be done by bubbling nitrogen carrier gas

generation. Because only one gas is introduced at a time,

through water.

there cannot be gas-phase reactions between precursors.

When the precursors are metal-organic compounds

(MOs), the technique is termed MOCVD. It is widely

33.4 MOCVD used in III-V compound semiconductor epitaxy, with

group III elements supplied as metal organics, such

Most CVD processes use simple source gases such as as trimethyl gallium Ga(CH 3 ) 3 or triethyl aluminium

silane and hydrides but there is the possibility of using Al(C 2 H 5 ) 3 , while group III precursors are usually

liquid precursors. A widely used liquid source for CVD hydrides, AsH 3 and PH 3 .