Page 350 - Sami Franssila Introduction to Microfabrication

P. 350

33

Tools for CVD and Epitaxy

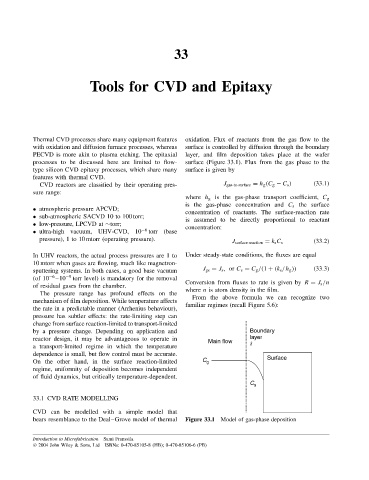

Thermal CVD processes share many equipment features oxidation. Flux of reactants from the gas flow to the

with oxidation and diffusion furnace processes, whereas surface is controlled by diffusion through the boundary

PECVD is more akin to plasma etching. The epitaxial layer, and film deposition takes place at the wafer

processes to be discussed here are limited to flow- surface (Figure 33.1). Flux from the gas phase to the

type silicon CVD epitaxy processes, which share many surface is given by

features with thermal CVD.

CVD reactors are classified by their operating pres- J gas-to-surface = h g (C g − C s ) (33.1)

sure range:

where h g is the gas-phase transport coefficient, C g

is the gas-phase concentration and C s the surface

• atmospheric pressure APCVD; concentration of reactants. The surface-reaction rate

• sub-atmospheric SACVD 10 to 100 torr; is assumed to be directly proportional to reactant

• low-pressure, LPCVD at ∼torr; concentration:

• ultra-high vacuum, UHV-CVD, 10 −6 torr (base

pressure), 1 to 10 mtorr (operating pressure).

J surface reaction = k s C s (33.2)

In UHV reactors, the actual process pressures are 1 to Under steady-state conditions, the fluxes are equal

10 mtorr when gases are flowing, much like magnetron-

sputtering systems. In both cases, a good base vacuum J gs = J s , or C s = C g /(1 + (k s /h g )) (33.3)

(of 10 −6 –10 −9 torr level) is mandatory for the removal Conversion from fluxes to rate is given by R = J s /n

of residual gases from the chamber. where n is atom density in the film.

The pressure range has profound effects on the

From the above formula we can recognize two

mechanism of film deposition. While temperature affects

familiar regimes (recall Figure 5.6):

the rate in a predictable manner (Arrhenius behaviour),

pressure has subtler effects: the rate-limiting step can

change from surface reaction-limited to transport-limited

by a pressure change. Depending on application and Boundary

reactor design, it may be advantageous to operate in Main flow layer

a transport-limited regime in which the temperature d

dependence is small, but flow control must be accurate. Surface

On the other hand, in the surface reaction-limited C g

regime, uniformity of deposition becomes independent

of fluid dynamics, but critically temperature-dependent.

C s

33.1 CVD RATE MODELLING

CVD can be modelled with a simple model that

bears resemblance to the Deal–Grove model of thermal Figure 33.1 Model of gas-phase deposition

Introduction to Microfabrication Sami Franssila

2004 John Wiley & Sons, Ltd ISBNs: 0-470-85105-8 (HB); 0-470-85106-6 (PB)