Page 151 - Know and Understand Centrifugal Pumps

P. 151

Know and Understand Centrifugal Pumps

H Problems induced by Operations.

Problems induced by Design.

H Problems induced by Maintenance.

Let's analyze the evidence that pump mechanics have seen so many

times. Consider the difference between a deflected shaft and a bent

shaft.

A bent shaft is physically bent and distorted. Placing the shaft into a

lathe or dynamic balancer and rotating it will reveal the distortion. If a

bent shaft is installed into a aupp and run, it will fail prematurely,

leaving evidence and specific signs on the circumference of close

tolerance stationary parts around the pump's volute circle. The shaft

will exhibit a wear spot on its surface where the close tolerance parts

were rubbing.

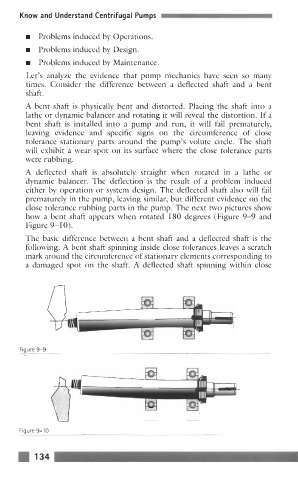

A deflected shaft is absolutely straight when rotated in a lathe or

dynamic balancer. The deflection is the result of a problem induced

either by operation or system design. The deflected shaft also will fail

prematurely in the pump, leaving similar, but different evidence on the

close tolerance rubbing parts in the pump. The next two pictures show

how a bent shaft appears when rotated 180 degrees (Figure 9-9 and

Figure 9-1 0).

The basic difference between a bent shaft and a deflected shaft is the

following. A bent shaft spinning inside close tolerances leaves a scratch

mark around the circumference of stationary elements corresponding to

a damaged spot on the shaft. A deflected shaft spinning within close

n

Figure 9-9

___~

U

Figure 9-10

134