Page 152 - Know and Understand Centrifugal Pumps

P. 152

Shaft Deflection

n

LJ LJ

Fiqure 9-11

Fiqure 9-12

tolerances leaves a scratch or gouged circle around the rotary element,

and a gouged or damaged spot on the stationary elements. It is

absolutely necessary to distinguish and recognize these significant

differences.

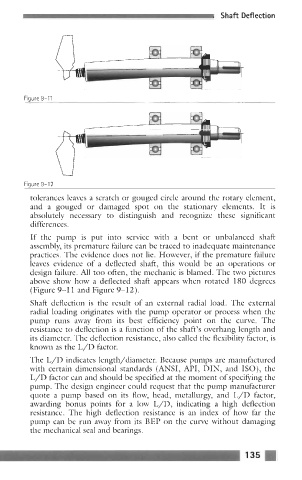

If the pump is put into service with a bent or unbalanced shaft

assembly, its premature failure can be traced to inadequate maintenance

practices. The evidence does not lie. However, if the premature failure

leaves evidence of a deflected shaft, this would be an operations or

design failure. All too often, the mechanic is blamed. The two pictures

above show how a deflected shaft appears when rotated 180 degrees

(Figure 9-11 and Figure 9-12).

Shaft deflection is the result of an external radial load. The external

radial loading originates with the pump operator or process when the

pump runs away from its best efficiency point on the curve. The

resistance to deflection is a function of the shaft’s overhang length and

its diameter. The deflection resistance, also called the flexibility factor, is

known as the L/D factor.

The L/D indicates length/diameter. Because pumps are manufactured

with certain dimensional standards (ANSI, API, DIN, and ISO), the

L/D factor can and should be specified at the moment of specifying the

pump. The design engineer could request that the pump manufacturer

quote a pump based on its flow, head, metallurgy, and L/D factor,

awarding bonus points for a low L/D, indicating a high deflection

resistance. The high deflection resistance is an index of how far the

pump can be run away from its BEP on the curve without damaging

the mechanical seal and bearings.

1 __ 135