Page 221 - Materials Chemistry, Second Edition

P. 221

EXERGY ANALYSIS AND ITS CONNECTION TO LIFE CYCLE ASSESSMENT 207

Fuel Electr. to grid HJO

Ex = 46.6 MJ Ex = 252 MJ m =19 kg

Electr.

Ex = 0.7 MJ

U (enriched) T_J Heat

Fuel (uranium) processing m = 0.00404 kg Nuclear plant Ex = 76.5 MJ Hydrogen plant

U (ore) TV = 26.7 % Ex = 1060MJ Ti = 36.4 % η β =93.2% ► H 2 m = 1 kg

m = 0.00729 kg! EX^ ^ 2916.3 MJ EX* = 673.8 MJ Electr. Ex = 118.2MJ

Ex = 3929 MJ Ex = 50.3 MJ

Electr.

D,0 Ex = 6.7 MJ

Heavy water ► 0 2 m = 8 kg

production

H'O

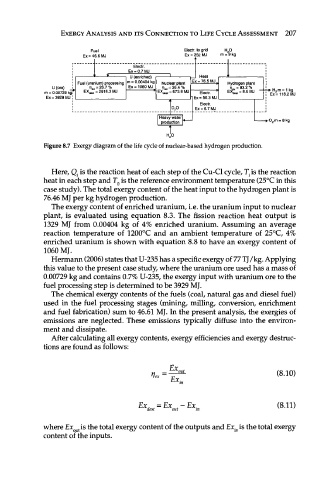

Figure 8.7 Exergy diagram of the life cycle of nuclear-based hydrogen production.

Here, Q. is the reaction heat of each step of the Cu-Cl cycle, T. is the reaction

heat in each step and T 0 is the reference environment temperature (25°C in this

case study). The total exergy content of the heat input to the hydrogen plant is

76.46 MJ per kg hydrogen production.

The exergy content of enriched uranium, i.e. the uranium input to nuclear

plant, is evaluated using equation 8.3. The fission reaction heat output is

1329 MJ from 0.00404 kg of 4% enriched uranium. Assuming an average

reaction temperature of 1200°C and an ambient temperature of 25°C, 4%

enriched uranium is shown with equation 8.8 to have an exergy content of

1060 MJ.

Hermann (2006) states that U-235 has a specific exergy of 77 TJ/kg. Applying

this value to the present case study, where the uranium ore used has a mass of

0.00729 kg and contains 0.7% U-235, the exergy input with uranium ore to the

fuel processing step is determined to be 3929 MJ.

The chemical exergy contents of the fuels (coal, natural gas and diesel fuel)

used in the fuel processing stages (mining, milling, conversion, enrichment

and fuel fabrication) sum to 46.61 MJ. In the present analysis, the exergies of

emissions are neglected. These emissions typically diffuse into the environ-

ment and dissipate.

After calculating all exergy contents, exergy efficiencies and exergy destruc-

tions are found as follows:

Ex

_ j^±out_

Vex = (8.10)

Ex-

Ex, =Ex -Ex. (8.11)

dest out v

where E* outis the total exergy content of the outputs and E* inis the total exergy

content of the inputs.