Page 376 - Lindens Handbook of Batteries

P. 376

LiTHiUM PriMAry BATTerieS 14.41

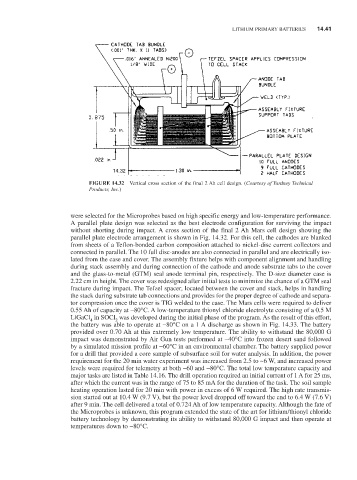

FIGURE 14.32 Vertical cross section of the final 2 Ah cell design. (Courtesy of Yardney Technical

Products, Inc.)

were selected for the Microprobes based on high specific energy and low-temperature performance.

A parallel plate design was selected as the best electrode configuration for surviving the impact

without shorting during impact. A cross section of the final 2 Ah Mars cell design showing the

parallel plate electrode arrangement is shown in Fig. 14.32. For this cell, the cathodes are blanked

from sheets of a Teflon-bonded carbon composition attached to nickel-disc current collectors and

connected in parallel. The 10 full disc-anodes are also connected in parallel and are electrically iso-

lated from the case and cover. The assembly fixture helps with component alignment and handling

during stack assembly and during connection of the cathode and anode substrate tabs to the cover

and the glass-to-metal (GTM) seal anode terminal pin, respectively. The D-size diameter case is

2.22 cm in height. The cover was redesigned after initial tests to minimize the chance of a GTM seal

fracture during impact. The Tefzel spacer, located between the cover and stack, helps in handling

the stack during substrate tab connections and provides for the proper degree of cathode and separa-

tor compression once the cover is TiG welded to the case. The Mars cells were required to deliver

0.55 Ah of capacity at -80°C. A low-temperature thionyl chloride electrolyte consisting of a 0.5 M

LiGaCl in SOCl was developed during the initial phase of the program. As the result of this effort,

4

2

the battery was able to operate at -80°C on a 1 A discharge as shown in Fig. 14.33. The battery

provided over 0.70 Ah at this extremely low temperature. The ability to withstand the 80,000 G

impact was demonstrated by Air Gun tests performed at -40°C into frozen desert sand followed

by a simulated mission profile at -60°C in an environmental chamber. The battery supplied power

for a drill that provided a core sample of subsurface soil for water analysis. in addition, the power

requirement for the 20 min water experiment was increased from 2.5 to ~6 W, and increased power

levels were required for telemetry at both -60 and -80°C. The total low temperature capacity and

major tasks are listed in Table 14.16. The drill operation required an initial current of 1 A for 25 ms,

after which the current was in the range of 75 to 85 mA for the duration of the task. The soil sample

heating operation lasted for 20 min with power in excess of 6 W required. The high rate transmis-

sion started out at 10.4 W (9.7 V), but the power level dropped off toward the end to 6.4 W (7.6 V)

after 9 min. The cell delivered a total of 0.724 Ah of low temperature capacity. Although the fate of

the Microprobes is unknown, this program extended the state of the art for lithium/thionyl chloride

battery technology by demonstrating its ability to withstand 80,000 G impact and then operate at

temperatures down to -80°C.