Page 146 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 146

136 Low-Temperature Energy Systems with Applications of Renewable Energy

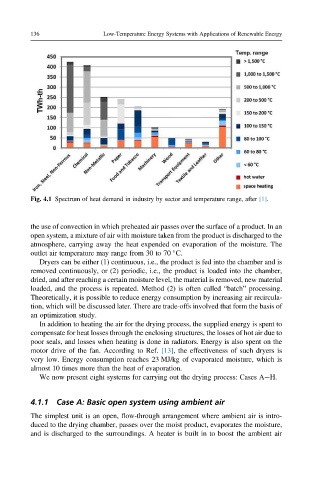

Fig. 4.1 Spectrum of heat demand in industry by sector and temperature range, after [1].

the use of convection in which preheated air passes over the surface of a product. In an

open system, a mixture of air with moisture taken from the product is discharged to the

atmosphere, carrying away the heat expended on evaporation of the moisture. The

outlet air temperature may range from 30 to 70 C.

Dryers can be either (1) continuous, i.e., the product is fed into the chamber and is

removed continuously, or (2) periodic, i.e., the product is loaded into the chamber,

dried, and after reaching a certain moisture level, the material is removed, new material

loaded, and the process is repeated. Method (2) is often called “batch” processing.

Theoretically, it is possible to reduce energy consumption by increasing air recircula-

tion, which will be discussed later. There are trade-offs involved that form the basis of

an optimization study.

In addition to heating the air for the drying process, the supplied energy is spent to

compensate for heat losses through the enclosing structures, the losses of hot air due to

poor seals, and losses when heating is done in radiators. Energy is also spent on the

motor drive of the fan. According to Ref. [13], the effectiveness of such dryers is

very low. Energy consumption reaches 23 MJ/kg of evaporated moisture, which is

almost 10 times more than the heat of evaporation.

We now present eight systems for carrying out the drying process: Cases AeH.

4.1.1 Case A: Basic open system using ambient air

The simplest unit is an open, flow-through arrangement where ambient air is intro-

duced to the drying chamber, passes over the moist product, evaporates the moisture,

and is discharged to the surroundings. A heater is built in to boost the ambient air