Page 150 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 150

140 Low-Temperature Energy Systems with Applications of Renewable Energy

0

00

streams (3 and 3 ) remix before passing over the condenser. As a result of the bypass,

the air temperature entering the condenser is higher since the bypass air is not cooled in

the evaporator; this reduces the heating load on the condenser. However, only a portion

of the moisture acquired by the drying air is removed in this case which means that the

air returning to the dryer carries more moisture than in Case E.

The efficiency of Case F operation is determined by the value of the bypass ratio a,

defined as the volume ratio of the bypass air to air passing through the evaporator, i.e.,

a ¼ v 3} =v 3 ; (4.1)

0

with reference to Fig. 4.5F.

The heat pump dryer with recirculation of the drying agent provides a significant

reduction in the specific energy consumption (SEC) compared to the traditional dryer

Case A.

The SEC of a heat pump dryer with recirculation, i.e., Case C, Fig. 4.4C with a flow

line from state 3 to state 2, is lower than the SEC of a traditional dryer with recircula-

tion (Case G) by about 50%. From Figs. 4.8 and 4.9, bypassing part of the air around

the heat pump evaporator (Case F) increases the energy efficiency of the drying plant

by 30e40% for different types of wood (Fig. 4.7).

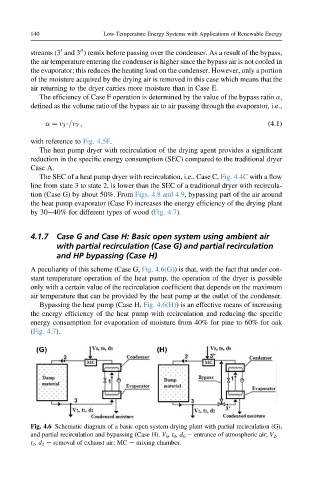

4.1.7 Case G and Case H: Basic open system using ambient air

with partial recirculation (Case G) and partial recirculation

and HP bypassing (Case H)

A peculiarity of this scheme (Case G, Fig. 4.6(G)) is that, with the fact that under con-

stant temperature operation of the heat pump, the operation of the dryer is possible

only with a certain value of the recirculation coefficient that depends on the maximum

air temperature that can be provided by the heat pump at the outlet of the condenser.

Bypassing the heat pump (Case H, Fig. 4.6(H)) is an effective means of increasing

the energy efficiency of the heat pump with recirculation and reducing the specific

energy consumption for evaporation of moisture from 40% for pine to 60% for oak

(Fig. 4.7).

Fig. 4.6 Schematic diagram of a basic open system drying plant with partial recirculation (G),

and partial recirculation and bypassing (Case H). V 0 ,t 0 ,d 0 e entrance of atmospheric air; V 2 ,

t 2 ,d 2 e removal of exhaust air; MC e mixing chamber.