Page 148 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 148

138 Low-Temperature Energy Systems with Applications of Renewable Energy

temperature t 2 ¼ 49 C and a constant moisture content of 0.10 kg/kg dry air. Process

00

2 /2 is an adiabatic process of cooling and humidifying the air in the dryer that fol-

0

lows a line of constant enthalpy to the outlet temperature of the air, in this example,

w28.3 C. It can be seen that the outlet relative humidity is w78% and the absolute

00

moisture is 0.19 kg/kg dry air. In an ideal adiabatic saturation process, point 2 would

move to the 100% relative humidity line. In practice, the dry- and wet-bulb tempera-

tures of the incoming air can be measured using a “sling psychrometer,” and the PC

can then be used to determine the relative humidity, absolute humidity and specific

enthalpy.

4.1.2 Case B: Open system using ambient air with a heat

recuperator

The next simplest system involves the use of a heater and a heat exchanger (recuper-

ator) in which the inlet air is preheated by the outlet flow of drying air (Fig. 4.2B). The

psychrometric chart (Fig. 4.3) shows the process of preheating the air in the recuper-

0

ator 1 / 2 and continued heating in the heat exchanger 2 / 2 . For the example

chosen, the recuperator covers the temperature increase from 20 to 25 C while the

heater (using external heat) takes care of the heating from 25 to 49 C. Without the

recuperator, heat energy of about 30.5 kJ/kg of dry air is needed to reach the desired

dryer inlet condition; with it, the energy requirement is reduced to about 17.5 kJ/kg, a

significant energy reduction of about 13 kJ/kg, or a 43% reduction. Process 3 / 4is

explained below.

Rotary regenerative heat exchangers e typical air preheaters used in many indus-

trial facilities e can also be used. The efficiency of using recuperative and regenerative

heat exchangers in some drying plants is shown in Refs. [16,17]. By using them, it is

possible to achieve 15e20% savings of primary energy spent on drying.

4.1.3 Case C: Open system using ambient air with a heat pump

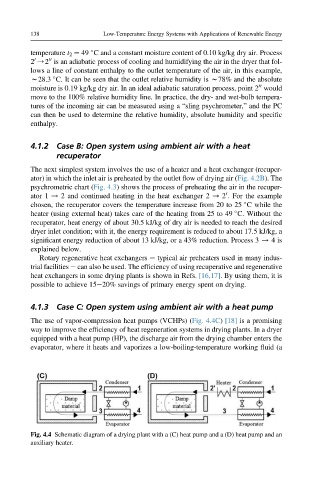

The use of vapor-compression heat pumps (VCHPs) (Fig. 4.4C) [18] is a promising

way to improve the efficiency of heat regeneration systems in drying plants. In a dryer

equipped with a heat pump (HP), the discharge air from the drying chamber enters the

evaporator, where it heats and vaporizes a low-boiling-temperature working fluid (a

Fig. 4.4 Schematic diagram of a drying plant with a (C) heat pump and a (D) heat pump and an

auxiliary heater.