Page 174 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 174

164 Low-Temperature Energy Systems with Applications of Renewable Energy

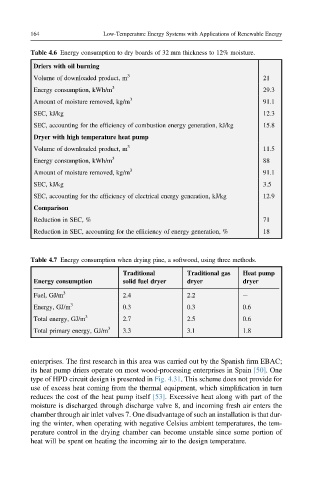

Table 4.6 Energy consumption to dry boards of 32 mm thickness to 12% moisture.

Driers with oil burning

Volume of downloaded product, m 3 21

Energy consumption, kWh/m 3 29.3

Amount of moisture removed, kg/m 3 91.1

SEC, kJ/kg 12.3

SEC, accounting for the efficiency of combustion energy generation, kJ/kg 15.8

Dryer with high temperature heat pump

Volume of downloaded product, m 3 11.5

Energy consumption, kWh/m 3 88

Amount of moisture removed, kg/m 3 91.1

SEC, kJ/kg 3.5

SEC, accounting for the efficiency of electrical energy generation, kJ/kg 12.9

Comparison

Reduction in SEC, % 71

Reduction in SEC, accounting for the efficiency of energy generation, % 18

Table 4.7 Energy consumption when drying pine, a softwood, using three methods.

Traditional Traditional gas Heat pump

Energy consumption solid fuel dryer dryer dryer

Fuel, GJ/m 3 2.4 2.2 e

Energy, GJ/m 3 0.3 0.3 0.6

Total energy, GJ/m 3 2.7 2.5 0.6

Total primary energy, GJ/m 3 3.3 3.1 1.8

enterprises. The first research in this area was carried out by the Spanish firm EBAC;

its heat pump driers operate on most wood-processing enterprises in Spain [50]. One

type of HPD circuit design is presented in Fig. 4.31. This scheme does not provide for

use of excess heat coming from the thermal equipment, which simplification in turn

reduces the cost of the heat pump itself [53]. Excessive heat along with part of the

moisture is discharged through discharge valve 8, and incoming fresh air enters the

chamber through air inlet valves 7. One disadvantage of such an installation is that dur-

ing the winter, when operating with negative Celsius ambient temperatures, the tem-

perature control in the drying chamber can become unstable since some portion of

heat will be spent on heating the incoming air to the design temperature.