Page 170 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 170

160 Low-Temperature Energy Systems with Applications of Renewable Energy

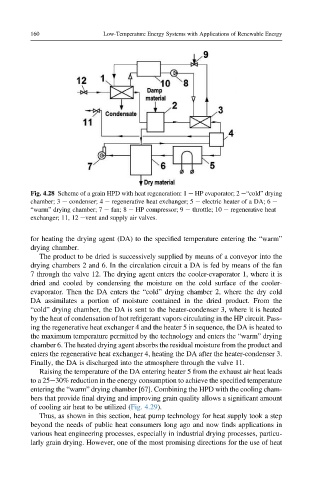

Fig. 4.28 Scheme of a grain HPD with heat regeneration: 1 e HP evaporator; 2 e“cold” drying

chamber; 3 e condenser; 4 e regenerative heat exchanger; 5 e electric heater of a DA; 6 e

“warm” drying chamber; 7 e fan; 8 e HP compressor; 9 e throttle; 10 e regenerative heat

exchanger; 11, 12 event and supply air valves.

for heating the drying agent (DA) to the specified temperature entering the “warm”

drying chamber.

The product to be dried is successively supplied by means of a conveyor into the

drying chambers 2 and 6. In the circulation circuit a DA is fed by means of the fan

7 through the valve 12. The drying agent enters the cooler-evaporator 1, where it is

dried and cooled by condensing the moisture on the cold surface of the cooler-

evaporator. Then the DA enters the “cold” drying chamber 2, where the dry cold

DA assimilates a portion of moisture contained in the dried product. From the

“cold” drying chamber, the DA is sent to the heater-condenser 3, where it is heated

by the heat of condensation of hot refrigerant vapors circulating in the HP circuit. Pass-

ing the regenerative heat exchanger 4 and the heater 5 in sequence, the DA is heated to

the maximum temperature permitted by the technology and enters the “warm” drying

chamber 6. The heated drying agent absorbs the residual moisture from the product and

enters the regenerative heat exchanger 4, heating the DA after the heater-condenser 3.

Finally, the DA is discharged into the atmosphere through the valve 11.

Raising the temperature of the DA entering heater 5 from the exhaust air heat leads

to a 25e30% reduction in the energy consumption to achieve the specified temperature

entering the “warm” drying chamber [67]. Combining the HPD with the cooling cham-

bers that provide final drying and improving grain quality allows a significant amount

of cooling air heat to be utilized (Fig. 4.29).

Thus, as shown in this section, heat pump technology for heat supply took a step

beyond the needs of public heat consumers long ago and now finds applications in

various heat engineering processes, especially in industrial drying processes, particu-

larly grain drying. However, one of the most promising directions for the use of heat