Page 166 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 166

156 Low-Temperature Energy Systems with Applications of Renewable Energy

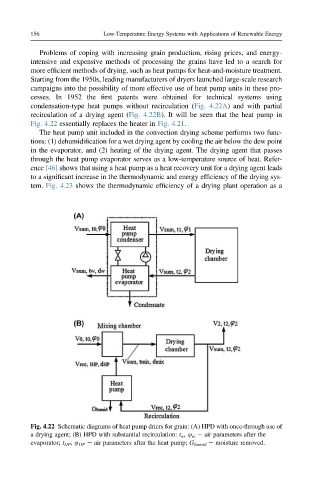

Problems of coping with increasing grain production, rising prices, and energy-

intensive and expensive methods of processing the grains have led to a search for

more efficient methods of drying, such as heat pumps for heat-and-moisture treatment.

Starting from the 1950s, leading manufacturers of dryers launched large-scale research

campaigns into the possibility of more effective use of heat pump units in these pro-

cesses. In 1952 the first patents were obtained for technical systems using

condensation-type heat pumps without recirculation (Fig. 4.22A) and with partial

recirculation of a drying agent (Fig. 4.22B). It will be seen that the heat pump in

Fig. 4.22 essentially replaces the heater in Fig. 4.21.

The heat pump unit included in the convection drying scheme performs two func-

tions: (1) dehumidification for a wet drying agent by cooling the air below the dew point

in the evaporator, and (2) heating of the drying agent. The drying agent that passes

through the heat pump evaporator serves as a low-temperature source of heat. Refer-

ence [46] shows that using a heat pump as a heat recovery unit for a drying agent leads

to a significant increase in the thermodynamic and energy efficiency of the drying sys-

tem. Fig. 4.23 shows the thermodynamic efficiency of a drying plant operation as a

Fig. 4.22 Schematic diagrams of heat pump driers for grain: (A) HPD with once-through use of

a drying agent; (B) HPD with substantial recirculation: t w , 4 w e air parameters after the

evaporator; t HP , 4 HP e air parameters after the heat pump; G humid e moisture removed.