Page 162 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 162

152 Low-Temperature Energy Systems with Applications of Renewable Energy

The exhaust air of the dryer is fed into the dehumidifier where it is cooled with wa-

ter to below the dew point. Water from the dehumidifier enters the evaporator of the

heat pump. The dried air is fed to a heater where it is heated by water coming from

the HP condenser. Additional heating is carried out in an electric heater. According

to the authors, the implementation of heat pump plants at all tea factories in Georgia

will save 100,000 tons of high-quality fuel oil annually.

Research carried out by scientists from many countries studying combinations of

HPD with additional sources of heat, namely, microwave energy, solar energy, energy

of infrared rays, radio frequency pulses, etc. deserve particular attention.

In References [34,35] studies of HPD in combination with microwave drying mech-

anisms were performed. The main conclusion is that the use of microwave energy dur-

ing the heat pump drying of food products and some of building materials can

significantly increase the productivity of the dryer and the quality of the products.

However, the cost of energy to operate microwave generators lowers the cost-

effectiveness of HPD to the level of traditional convection drying plants.

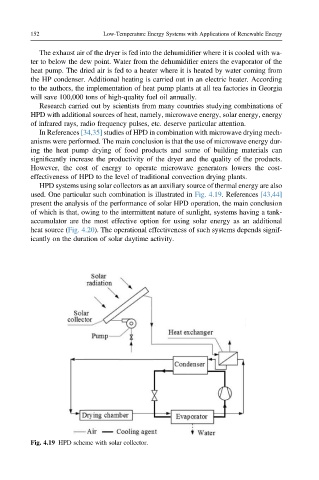

HPD systems using solar collectors as an auxiliary source of thermal energy are also

used. One particular such combination is illustrated in Fig. 4.19. References [43,44]

present the analysis of the performance of solar HPD operation, the main conclusion

of which is that, owing to the intermittent nature of sunlight, systems having a tank-

accumulator are the most effective option for using solar energy as an additional

heat source (Fig. 4.20). The operational effectiveness of such systems depends signif-

icantly on the duration of solar daytime activity.

Fig. 4.19 HPD scheme with solar collector.