Page 159 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 159

Heat pumps in the drying industry 149

various crops dried in 2-stage heat pump driers. According to the authors’ data, with

correctly selected technical parameters for the process and a given frequency of oper-

ation variation of temperature, the degradation of a very important quality indicator for

food products, namely, color, may be reduced by 87%.

The ability to control the drying conditions quickly and efficiently is another advan-

tage of heat pump technology for drying food products. In countries where humidity is

high, a large percentage of defective products is observed during the rainy seasons due

to high humidity of the air used as the drying agent. In such cases, the HPD can reduce

production costs by means of controlling the moisture content of the product by regu-

lating the removal of moisture and the latent heat of vapor formation from the air in the

evaporator.

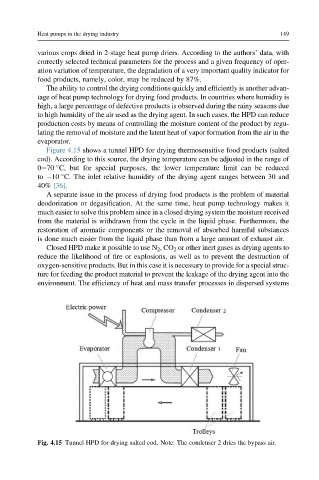

Figure 4.15 shows a tunnel HPD for drying thermosensitive food products (salted

cod). According to this source, the drying temperature can be adjusted in the range of

0e70 C, but for special purposes, the lower temperature limit can be reduced

to 10 C. The inlet relative humidity of the drying agent ranges between 30 and

40% [36].

A separate issue in the process of drying food products is the problem of material

deodorization or degasification. At the same time, heat pump technology makes it

much easier to solve this problem since in a closed drying system the moisture received

from the material is withdrawn from the cycle in the liquid phase. Furthermore, the

restoration of aromatic components or the removal of absorbed harmful substances

is done much easier from the liquid phase than from a large amount of exhaust air.

Closed HPD make it possible to use N 2 ,CO 2 or other inert gases as drying agents to

reduce the likelihood of fire or explosions, as well as to prevent the destruction of

oxygen-sensitive products. But in this case it is necessary to provide for a special struc-

ture for feeding the product material to prevent the leakage of the drying agent into the

environment. The efficiency of heat and mass transfer processes in dispersed systems

Fig. 4.15 Tunnel HPD for drying salted cod. Note: The condenser 2 dries the bypass air.