Page 228 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 228

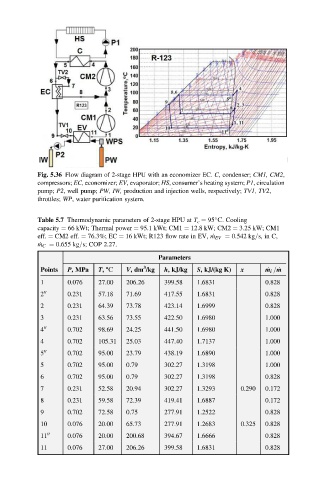

Fig. 5.36 Flow diagram of 2-stage HPU with an economizer EC. C, condenser; CM1, CM2,

compressors; EC, economizer; EV, evaporator; HS, consumer’s heating system; P1, circulation

pump; P2, well pump; PW, IW, production and injection wells, respectively; TV1, TV2,

throttles; WP, water purification system.

Table 5.7 Thermodynamic parameters of 2-stage HPU at T c ¼ 95 S. Cooling

capacity ¼ 66 kWt; Thermal power ¼ 95.1 kWt; CM1 ¼ 12.8 kW; CM2 ¼ 3.25 kW; CM1

eff. ¼ CM2 eff. ¼ 76.3%; EC ¼ 16 kWt; R123 flow rate in EV, _ m EV ¼ 0.542 kg=s, in C,

_ m C ¼ 0.655 kg=s; COP 2.27.

Parameters

3

Points P, MPa T, 8S V,dm /kg h, kJ/kg S, kJ/(kg K) x _ m i = _ m

1 0.076 27.00 206.26 399.58 1.6831 0.828

2 00 0.231 57.18 71.69 417.55 1.6831 0.828

2 0.231 64.39 73.78 423.14 1.6999 0.828

3 0.231 63.56 73.55 422.50 1.6980 1.000

4 00 0.702 98.69 24.25 441.50 1.6980 1.000

4 0.702 105.31 25.03 447.40 1.7137 1.000

5 00 0.702 95.00 23.79 438.19 1.6890 1.000

5 0.702 95.00 0.79 302.27 1.3198 1.000

6 0.702 95.00 0.79 302.27 1.3198 0.828

7 0.231 52.58 20.94 302.27 1.3293 0.290 0.172

8 0.231 59.58 72.39 419.41 1.6887 0.172

9 0.702 72.58 0.75 277.91 1.2522 0.828

10 0.076 20.00 65.73 277.91 1.2683 0.325 0.828

11 00 0.076 20.00 200.68 394.67 1.6666 0.828

11 0.076 27.00 206.26 399.58 1.6831 0.828