Page 286 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 286

272 Low-Temperature Energy Systems with Applications of Renewable Energy

Fig. 7.12 HOST microferm biogas installation, Angers, France [18].

The technology of methane fermentation in a bioreactor requires compliance with

the limits of temperature regimes, and the intensification of heat exchange between the

heater and the substrate through mixing. A facility in Angers, France is shown in

Fig. 7.12, and a diagram for the simulation of energy-saving heat and mass exchange

processes in a bioreactor with a mixing device is shown in Fig. 7.13.

The mass exchange process (conservation of mass) in the bioreactor is described by

the formula:

0

m sub ¼ m sub þ m g (7.2)

where m sub is specific mass of substrate [M sub e substrate mass in the biogas plant]

0

loaded into the reactor, kg; m sub is mass of the substrate after processing in the

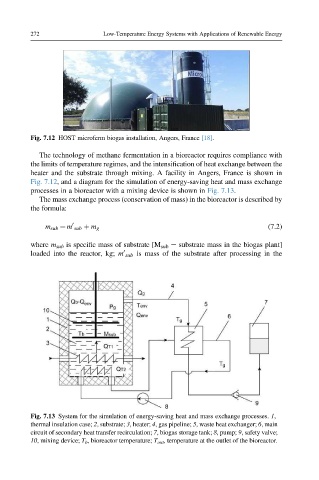

Fig. 7.13 System for the simulation of energy-saving heat and mass exchange processes. 1,

thermal insulation case; 2, substrate; 3, heater; 4, gas pipeline; 5, waste heat exchanger; 6, main

circuit of secondary heat transfer recirculation; 7, biogas storage tank; 8, pump; 9, safety valve;

10, mixing device; T b , bioreactor temperature; T out , temperature at the outlet of the bioreactor.