Page 204 - MEMS Mechanical Sensors

P. 204

8.2 Micromachined Accelerometer 193

Fixed polysilicon

capacitor plates

Suspension

system Anchor

1.8V Ref.

Output

voltage

Demodulator

Buffer and lowpass Preamp

filter

3MΩ

Polysilicon proof Feedback voltage

mass and

moving

electrodes Square wave

oscillator

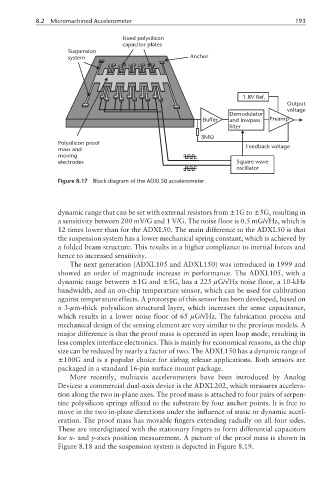

Figure 8.17 Block diagram of the ADXL50 accelerometer.

dynamic range that can be set with external resistors from ±1G to ±5G, resulting in

a sensitivity between 200 mV/G and 1 V/G. The noise floor is 0.5 mG/√Hz, which is

12 times lower than for the ADXL50. The main difference to the ADXL50 is that

the suspension system has a lower mechanical spring constant, which is achieved by

a folded beam structure. This results in a higher compliance to inertial forces and

hence to increased sensitivity.

The next generation (ADXL105 and ADXL150) was introduced in 1999 and

showed an order of magnitude increase in performance. The ADXL105, with a

dynamic range between ±1G and ±5G, has a 225 µG/√Hz noise floor, a 10-kHz

bandwidth, and an on-chip temperature sensor, which can be used for calibration

against temperature effects. A prototype of this sensor has been developed, based on

a3-µm-thick polysilicon structural layer, which increases the sense capacitance,

which results in a lower noise floor of 65 µG/√Hz. The fabrication process and

mechanical design of the sensing element are very similar to the previous models. A

major difference is that the proof mass is operated in open loop mode, resulting in

less complex interface electronics. This is mainly for economical reasons, as the chip

size can be reduced by nearly a factor of two. The ADXL150 has a dynamic range of

±100G and is a popular choice for airbag release applications. Both sensors are

packaged in a standard 16-pin surface mount package.

More recently, multiaxis accelerometers have been introduced by Analog

Devices: a commercial dual-axis device is the ADXL202, which measures accelera-

tion along the two in-plane axes. The proof mass is attached to four pairs of serpen-

tine polysilicon springs affixed to the substrate by four anchor points. It is free to

move in the two in-plane directions under the influence of static or dynamic accel-

eration. The proof mass has movable fingers extending radially on all four sides.

These are interdigitated with the stationary fingers to form differential capacitors

for x- and y-axes position measurement. A picture of the proof mass is shown in

Figure 8.18 and the suspension system is depicted in Figure 8.19.