Page 242 - MEMS Mechanical Sensors

P. 242

9.3 Pressure Difference Flow Sensors 231

Capacitive

Flow restriction pressure sensors

++

p -silicon

p 1

Pyrex

Silicon

p 2 p 2

p 1

Glass Pyrex

p 1 p 2 Input Flow Output

Inlet Capacitor flow channel

Outlet flow

(a) (b)

Flow restriction

Sensor

diaphragm

Flow

Piezoresistor ZnO thin film ring

Polyimide

p 2

membrane Sensor A Sensor B

p 1

Silicon

Orifice Silicon

Inlet Outlet

Flow restriction

(c) (d)

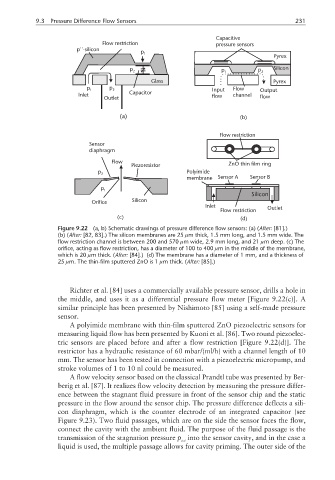

Figure 9.22 (a, b) Schematic drawings of pressure difference flow sensors: (a) (After: [81].)

(b) (After: [82, 83].) The silicon membranes are 25 µm thick, 1.5 mm long, and 1.5 mm wide. The

flow restriction channel is between 200 and 570 µm wide, 2.9 mm long, and 21 µm deep. (c) The

orifice, acting as flow restriction, has a diameter of 100 to 400 µm in the middle of the membrane,

which is 20 µm thick. (After: [84].) (d) The membrane has a diameter of 1 mm, and a thickness of

25 µm. The thin-film sputtered ZnO is 1 µm thick. (After: [85].)

Richter et al. [84] uses a commercially available pressure sensor, drills a hole in

the middle, and uses it as a differential pressure flow meter [Figure 9.22(c)]. A

similar principle has been presented by Nishimoto [85] using a self-made pressure

sensor.

A polyimide membrane with thin-film sputtered ZnO piezoelectric sensors for

measuring liquid flow has been presented by Kuoni et al. [86]. Two round piezoelec-

tric sensors are placed before and after a flow restriction [Figure 9.22(d)]. The

restrictor has a hydraulic resistance of 60 mbar/(ml/h) with a channel length of 10

mm. The sensor has been tested in connection with a piezoelectric micropump, and

stroke volumes of 1 to 10 nl could be measured.

A flow velocity sensor based on the classical Prandtl tube was presented by Ber-

berig et al. [87]. It realizes flow velocity detection by measuring the pressure differ-

ence between the stagnant fluid pressure in front of the sensor chip and the static

pressure in the flow around the sensor chip. The pressure difference deflects a sili-

con diaphragm, which is the counter electrode of an integrated capacitor (see

Figure 9.23). Two fluid passages, which are on the side the sensor faces the flow,

connect the cavity with the ambient fluid. The purpose of the fluid passage is the

transmission of the stagnation pressure p into the sensor cavity, and in the case a

tot

liquid is used, the multiple passage allows for cavity priming. The outer side of the