Page 243 - MEMS Mechanical Sensors

P. 243

232 Flow Sensors

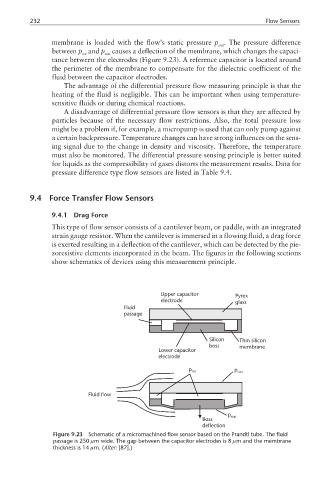

membrane is loaded with the flow’s static pressure p . The pressure difference

stat

between p and p causes a deflection of the membrane, which changes the capaci-

tot stat

tance between the electrodes (Figure 9.23). A reference capacitor is located around

the perimeter of the membrane to compensate for the dielectric coefficient of the

fluid between the capacitor electrodes.

The advantage of the differential pressure flow measuring principle is that the

heating of the fluid is negligible. This can be important when using temperature-

sensitive fluids or during chemical reactions.

A disadvantage of differential pressure flow sensors is that they are affected by

particles because of the necessary flow restrictions. Also, the total pressure loss

might be a problem if, for example, a micropump is used that can only pump against

a certain backpressure. Temperature changes can have strong influences on the sens-

ing signal due to the change in density and viscosity. Therefore, the temperature

must also be monitored. The differential pressure sensing principle is better suited

for liquids as the compressibility of gases distorts the measurement results. Data for

pressure difference type flow sensors are listed in Table 9.4.

9.4 Force Transfer Flow Sensors

9.4.1 Drag Force

This type of flow sensor consists of a cantilever beam, or paddle, with an integrated

strain gauge resistor. When the cantilever is immersed in a flowing fluid, a drag force

is exerted resulting in a deflection of the cantilever, which can be detected by the pie-

zoresistive elements incorporated in the beam. The figures in the following sections

show schematics of devices using this measurement principle.

Upper capacitor Pyrex

electrode glass

Fluid

passage

Silicon Thin silicon

boss membrane

Lower capacitor

electrode

p tot p stat

Fluid flow

p stat

Boss

deflection

Figure 9.23 Schematic of a micromachined flow sensor based on the Prandtl tube. The fluid

passage is 250 µm wide. The gap between the capacitor electrodes is 8 µm and the membrane

thickness is 14 µm. (After: [87].)