Page 247 - MEMS Mechanical Sensors

P. 247

236 Flow Sensors

Upstream

Frame airfoil plate

Upstream Lift force

airfoil plate

Flow

Center

Drag force support

beam Stress

concentrating

Central Piezo- beam

support resistor

beam Downstream

airfoil plate Downstream

airfoil plate

(a) (b)

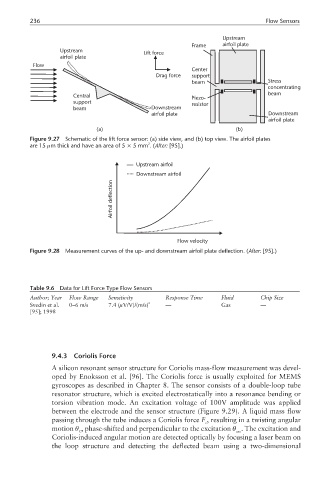

Figure 9.27 Schematic of the lift force sensor: (a) side view, and (b) top view. The airfoil plates

2

are 15 µm thick and have an area of 5 × 5mm .(After: [95].)

Upstream airfoil

Downstream airfoil

deflection

Airfoil

Flow velocity

Figure 9.28 Measurement curves of the up- and downstream airfoil plate deflection. (After: [95].)

Table 9.6 Data for Lift Force Type Flow Sensors

Author; Year Flow Range Sensitivity Response Time Fluid Chip Size

Svedin et al. 0–6 m/s 7.4 (µV/V)/(m/s) 2 — Gas —

[95]; 1998

9.4.3 Coriolis Force

A silicon resonant sensor structure for Coriolis mass-flow measurement was devel-

oped by Enoksson et al. [96]. The Coriolis force is usually exploited for MEMS

gyroscopes as described in Chapter 8. The sensor consists of a double-loop tube

resonator structure, which is excited electrostatically into a resonance bending or

torsion vibration mode. An excitation voltage of 100V amplitude was applied

between the electrode and the sensor structure (Figure 9.29). A liquid mass flow

passing through the tube induces a Coriolis force F , resulting in a twisting angular

c

motion θ , phase-shifted and perpendicular to the excitation θ . The excitation and

C exc

Coriolis-induced angular motion are detected optically by focusing a laser beam on

the loop structure and detecting the deflected beam using a two-dimensional