Page 245 - MEMS Mechanical Sensors

P. 245

234 Flow Sensors

Flow

(from the front)

Flow

Paddle

Piezoresistive

elements

Beam Strain

gauge

(a) (b)

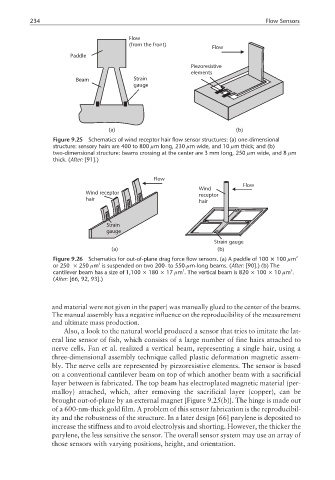

Figure 9.25 Schematics of wind receptor hair flow sensor structures: (a) one-dimensional

structure: sensory hairs are 400 to 800 µm long, 230 µm wide, and 10 µm thick; and (b)

two-dimensional structure: beams crossing at the center are 3 mm long, 250 µm wide, and 8 µm

thick. (After: [91].)

Flow

Flow

Wind

Wind receptor receptor

hair

hair

Strain

gauge

Strain gauge

(a) (b)

Figure 9.26 Schematics for out-of-plane drag force flow sensors. (a) A paddle of 100 × 100 µm 2

2

or 250 × 250 µm is suspended on two 200- to 550-µm-long beams. (After: [90].) (b) The

3

3

cantilever beam has a size of 1,100 × 180 × 17 µm . The vertical beam is 820 × 100 × 10 µm .

(After: [66, 92, 93].)

and material were not given in the paper) was manually glued to the center of the beams.

The manual assembly has a negative influence on the reproducibility of the measurement

and ultimate mass production.

Also, a look to the natural world produced a sensor that tries to imitate the lat-

eral line sensor of fish, which consists of a large number of fine hairs attached to

nerve cells. Fan et al. realized a vertical beam, representing a single hair, using a

three-dimensional assembly technique called plastic deformation magnetic assem-

bly. The nerve cells are represented by piezoresistive elements. The sensor is based

on a conventional cantilever beam on top of which another beam with a sacrificial

layer between is fabricated. The top beam has electroplated magnetic material (per-

malloy) attached, which, after removing the sacrificial layer (copper), can be

brought out-of-plane by an external magnet [Figure 9.25(b)]. The hinge is made out

of a 600-nm-thick gold film. A problem of this sensor fabrication is the reproducibil-

ity and the robustness of the structure. In a later design [66] parylene is deposited to

increase the stiffness and to avoid electrolysis and shorting. However, the thicker the

parylene, the less sensitive the sensor. The overall sensor system may use an array of

those sensors with varying positions, height, and orientation.