Page 253 - MEMS Mechanical Sensors

P. 253

242 Flow Sensors

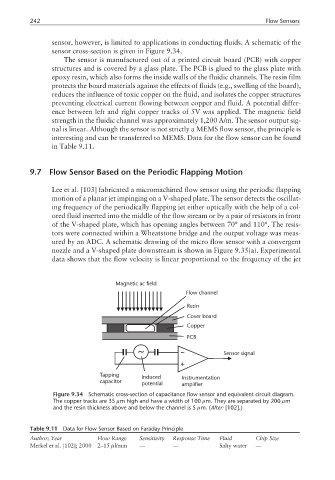

sensor, however, is limited to applications in conducting fluids. A schematic of the

sensor cross-section is given in Figure 9.34.

The sensor is manufactured out of a printed circuit board (PCB) with copper

structures and is covered by a glass plate. The PCB is glued to the glass plate with

epoxy resin, which also forms the inside walls of the fluidic channels. The resin film

protects the board materials against the effects of fluids (e.g., swelling of the board),

reduces the influence of toxic copper on the fluid, and isolates the copper structures

preventing electrical current flowing between copper and fluid. A potential differ-

ence between left and right copper tracks of 5V was applied. The magnetic field

strength in the fluidic channel was approximately 1,200 A/m. The sensor output sig-

nal is linear. Although the sensor is not strictly a MEMS flow sensor, the principle is

interesting and can be transferred to MEMS. Data for the flow sensor can be found

in Table 9.11.

9.7 Flow Sensor Based on the Periodic Flapping Motion

Lee et al. [103] fabricated a micromachined flow sensor using the periodic flapping

motion of a planar jet impinging on a V-shaped plate. The sensor detects the oscillat-

ing frequency of the periodically flapping jet either optically with the help of a col-

ored fluid inserted into the middle of the flow stream or by a pair of resistors in front

of the V-shaped plate, which has opening angles between 70° and 110°. The resis-

tors were connected within a Wheatstone bridge and the output voltage was meas-

ured by an ADC. A schematic drawing of the micro flow sensor with a convergent

nozzle and a V-shaped plate downstream is shown in Figure 9.35(a). Experimental

data shows that the flow velocity is linear proportional to the frequency of the jet

Magnetic ac field

Flow channel

Resin

Cover board

Copper

PCB

Sensor signal

Tapping Induced Instrumentation

capacitor potential amplifier

Figure 9.34 Schematic cross-section of capacitance flow sensor and equivalent circuit diagram.

The copper tracks are 35 µm high and have a width of 100 µm. They are separated by 200 µm

and the resin thickness above and below the channel is 5 µm. (After: [102].)

Table 9.11 Data for Flow Sensor Based on Faraday Principle

Author; Year Flow Range Sensitivity Response Time Fluid Chip Size

Merkel et al. [102]; 2000 2–15 µl/min — — Salty water —