Page 184 - MEMS and Microstructures in Aerospace Applications

P. 184

Osiander / MEMS and microstructures in Aerospace applications DK3181_c008 Final Proof page 174 1.9.2005 12:05pm

174 MEMS and Microstructures in Aerospace Applications

Target Sub-window

field coverage

Target beam

(670 nm)

Target beam (635 nm)

Galvanometer

Beam

splitter

MEMS

micro-minor

Dichroic

fitter

Collimator Camera Collimator

lens

Tip/tilt CMOS Laser

voltage Laser camera

Function

generator

Leg 1-2-3 voltages

USB2

High-speed DSP/FPGA DSP MatLab Simulink CMDS

DAC board board Ethernet system camera

driver Centroid code driver

DSP/FPGA system Personal computer

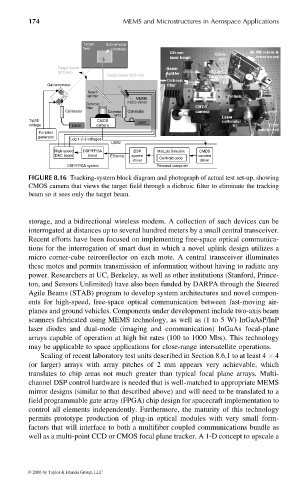

FIGURE 8.16 Tracking-system block diagram and photograph of actual test set-up, showing

CMOS camera that views the target field through a dichroic filter to eliminate the tracking

beam so it sees only the target beam.

storage, and a bidirectional wireless modem. A collection of such devices can be

interrogated at distances up to several hundred meters by a small central transceiver.

Recent efforts have been focused on implementing free-space optical communica-

tions for the interrogation of smart dust in which a novel uplink design utilizes a

micro corner-cube retroreflector on each mote. A central transceiver illuminates

these motes and permits transmission of information without having to radiate any

power. Researchers at UC, Berkeley, as well as other institutions (Stanford, Prince-

ton, and Sensors Unlimited) have also been funded by DARPA through the Steered

Agile Beams (STAB) program to develop system architectures and novel compon-

ents for high-speed, free-space optical communication between fast-moving air-

planes and ground vehicles. Components under development include two-axis beam

scanners fabricated using MEMS technology, as well as (1 to 5 W) InGaAsP/InP

laser diodes and dual-mode (imaging and communication) InGaAs focal-plane

arrays capable of operation at high bit rates (100 to 1000 Mbs). This technology

may be applicable to space applications for close-range intersatellite operations.

Scaling of recent laboratory test units described in Section 8.6.1 to at least 4 4

(or larger) arrays with array pitches of 2 mm appears very achievable, which

translates to chip areas not much greater than typical focal plane arrays. Multi-

channel DSP control hardware is needed that is well-matched to appropriate MEMS

mirror designs (similar to that described above) and will need to be translated to a

field programmable gate array (FPGA) chip design for spacecraft implementation to

control all elements independently. Furthermore, the maturity of this technology

permits prototype production of plug-in optical modules with very small form-

factors that will interface to both a multifiber coupled communications bundle as

well as a multi-point CCD or CMOS focal plane tracker. A 1-D concept to upscale a

© 2006 by Taylor & Francis Group, LLC