Page 284 - MEMS and Microstructures in Aerospace Applications

P. 284

Osiander / MEMS and microstructures in Aerospace applications DK3181_c012 Final Proof page 276 1.9.2005 9:13pm

276 MEMS and Microstructures in Aerospace Applications

Voids in the die-attach material cause areas of localized stress concentration

that can lead to premature delamination. Presently, MEMS packages use

solders, adhesives, or epoxies for die attach. Each method has advantages and

disadvantages that affect the overall MEMS reliability. Generally, when a solder

is used, the silicon die would have a gold backing. Au–Sn (80–20) solder generally

is used and forms an Au–Sn eutectic when the assembly is heated to approximately

2508C in the presence of a forming gas. When this method is applied, a single rigid

assembled part with low thermal and electrical resistances between the MEMS

device and the package is obtained. One problem with this attachment method

is that the solder attach is rigid (and brittle) which means it is critical for the

MEMS device and the package CTEs to match since the solder cannot absorb

the stresses.

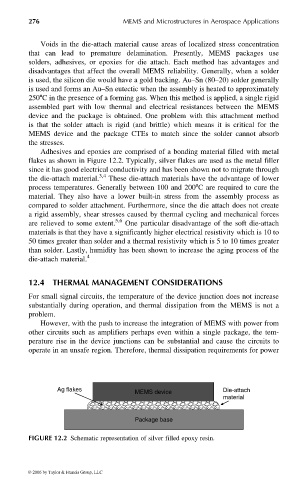

Adhesives and epoxies are comprised of a bonding material filled with metal

flakes as shown in Figure 12.2. Typically, silver flakes are used as the metal filler

since it has good electrical conductivity and has been shown not to migrate through

the die-attach material. 3,4 These die-attach materials have the advantage of lower

process temperatures. Generally between 100 and 2008C are required to cure the

material. They also have a lower built-in stress from the assembly process as

compared to solder attachment. Furthermore, since the die attach does not create

a rigid assembly, shear stresses caused by thermal cycling and mechanical forces

are relieved to some extent. 5,6 One particular disadvantage of the soft die-attach

materials is that they have a significantly higher electrical resistivity which is 10 to

50 times greater than solder and a thermal resistivity which is 5 to 10 times greater

than solder. Lastly, humidity has been shown to increase the aging process of the

die-attach material. 4

12.4 THERMAL MANAGEMENT CONSIDERATIONS

For small signal circuits, the temperature of the device junction does not increase

substantially during operation, and thermal dissipation from the MEMS is not a

problem.

However, with the push to increase the integration of MEMS with power from

other circuits such as amplifiers perhaps even within a single package, the tem-

perature rise in the device junctions can be substantial and cause the circuits to

operate in an unsafe region. Therefore, thermal dissipation requirements for power

Ag flakes Die-attach

MEMS device

material

Package base

FIGURE 12.2 Schematic representation of silver filled epoxy resin.

© 2006 by Taylor & Francis Group, LLC