Page 370 - MEMS and Microstructures in Aerospace Applications

P. 370

Osiander / MEMS and microstructures in Aerospace applications DK3181_c016 Final Proof page 363 1.9.2005 12:56pm

Microelectromechanical Systems and Microstructures in Aerospace 363

16.5.1.3 Test Methodology

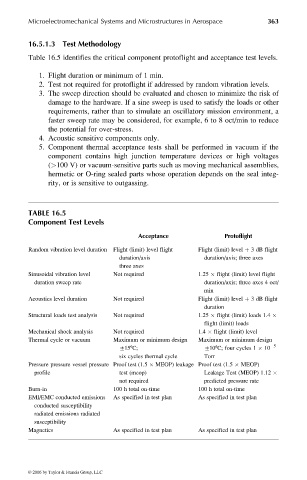

Table 16.5 identifies the critical component protoflight and acceptance test levels.

1. Flight duration or minimum of 1 min.

2. Test not required for protoflight if addressed by random vibration levels.

3. The sweep direction should be evaluated and chosen to minimize the risk of

damage to the hardware. If a sine sweep is used to satisfy the loads or other

requirements, rather than to simulate an oscillatory mission environment, a

faster sweep rate may be considered, for example, 6 to 8 oct/min to reduce

the potential for over-stress.

4. Acoustic sensitive components only.

5. Component thermal acceptance tests shall be performed in vacuum if the

component contains high junction temperature devices or high voltages

(>100 V) or vacuum-sensitive parts such as moving mechanical assemblies,

hermetic or O-ring sealed parts whose operation depends on the seal integ-

rity, or is sensitive to outgassing.

TABLE 16.5

Component Test Levels

Acceptance Protoflight

Random vibration level duration Flight (limit) level flight Flight (limit) level þ 3 dB flight

duration/axis duration/axis; three axes

three axes

Sinusoidal vibration level Not required 1.25 flight (limit) level flight

duration sweep rate duration/axis; three axes 4 oct/

min

Acoustics level duration Not required Flight (limit) level þ 3 dB flight

duration

Structural loads test analysis Not required 1.25 flight (limit) loads 1.4

flight (limit) loads

Mechanical shock analysis Not required 1.4 flight (limit) level

Thermal cycle or vacuum Maximum or minimum design Maximum or minimum design

+158C; +108C; four cycles 1 10 5

six cycles thermal cycle Torr

Pressure pressure vessel pressure Proof test (1.5 MEOP) leakage Proof test (1.5 MEOP)

profile test (meop) Leakage Test (MEOP) 1.12

not required predicted pressure rate

Burn-in 100 h total on-time 100 h total on-time

EMI/EMC conducted emissions As specified in test plan As specified in test plan

conducted susceptibility

radiated emissions radiated

susceptibility

Magnetics As specified in test plan As specified in test plan

© 2006 by Taylor & Francis Group, LLC