Page 332 -

P. 332

LIGA and Micromolding 4-73

Fiber-chip coupling

Protective layer LWL

Optical fiber

Spring elements

Fixed guide Step for coating

structure support

Cutting surface

Substrate

Space for insertion

of integrated

optical chip

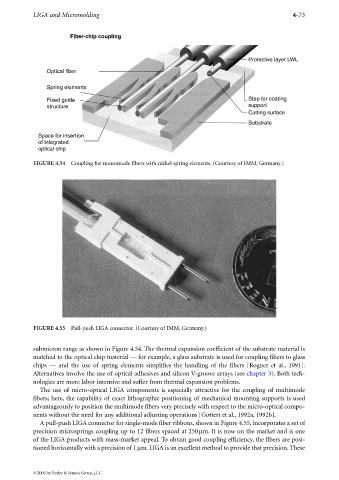

FIGURE 4.54 Coupling for monomode fibers with nickel spring elements. (Courtesy of IMM, Germany.)

FIGURE 4.55 Pull-push LIGA connector. (Courtesy of IMM, Germany.)

submicron range as shown in Figure 4.54. The thermal expansion coefficient of the substrate material is

matched to the optical chip material — for example, a glass substrate is used for coupling fibers to glass

chips — and the use of spring elements simplifies the handling of the fibers [Rogner et al., 1991].

Alternatives involve the use of optical adhesives and silicon V-groove arrays (see chapter 3). Both tech-

nologies are more labor intensive and suffer from thermal expansion problems.

The use of micro-optical LIGA components is especially attractive for the coupling of multimode

fibers; here, the capability of exact lithographic positioning of mechanical mounting supports is used

advantageously to position the multimode fibers very precisely with respect to the micro-optical compo-

nents without the need for any additional adjusting operations [Gottert et al., 1992a, 1992b].

A pull-push LIGA connector for single-mode fiber ribbons, shown in Figure 4.55, incorporates a set of

precision microsprings coupling up to 12 fibers spaced at 250µm. It is now on the market and is one

of the LIGA products with mass-market appeal. To obtain good coupling efficiency, the fibers are posi-

tioned horizontally with a precision of 1 µm. LIGA is an excellent method to provide that precision. These

© 2006 by Taylor & Francis Group, LLC