Page 243 - Machinery Component Maintenance

P. 243

Machinery Alignment 225

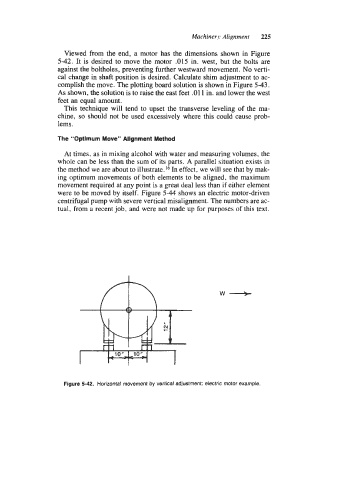

Viewed from the end, a motor has the dimensions shown in Figure

5-42. It is desired to move the motor .015 in. west, but the bolts are

against the boltholes, preventing further westward movement. No verti-

cal change in shaft position is desired. Calculate shim adjustment to ac-

complish the move. The plotting board solution is shown in Figure 5-43.

As shown, the solution is to raise the east feet .011 in. and lower the west

feet an equal amount.

This technique will tend to upset the transverse leveling of the ma-

chine, so should not be used excessively where this could cause prob-

lems.

The “Optimum Move” Alignment Method

At times, as in mixing alcohol with water and measuring volumes, the

whole can be less than the sum of its parts. A parallel situation exists in

the method we are about to illustrate.I6 In effect, we will see that by mak-

ing optimum movements of both elements to be aligned, the maximum

movement required at any point is a great deal less than if either element

were to be moved by itself. Figure 5-44 shows an electric motor-driven

centrifugal pump with severe vertical misalignment. The numbers are ac-

tual, from a recent job, and were not made up for purposes of this text.

Figure 5-42. Horizontal movement by vertical adjustment: electric motor example.