Page 246 - Machinery Component Maintenance

P. 246

228 Machinery Component Maintenance and Repair

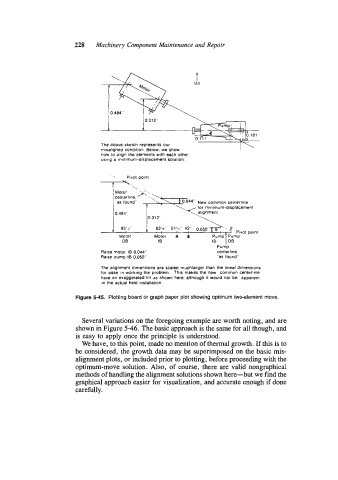

The above sketch represents our I

misaligned condition Below we show

now to ahgn the elements with each other

usmg a minimum-displacement solution

.. Pivot point

t.

..

Motor /A, '-.. ':".,

centerline.

as found" + .'.'\;"'' New common centerline

for minimum-displacement

-.

< alignment

0 484"

0.3 12" --\

L.

*

1 85'2 i 63'n 51'~ 42 0050 -@ 0

7 Pivot point

Motor Motor A 8 Pump Pump

OB IB IB OB

Pump

Raise motor 18 0.044" centerline.

Raise pump IB 0.050'' "as found"

The alignment dimensions are scaled muchlarger than the linear dimensions

for ease in working the problem This makes the new common centerline

have an exaggerated tilt as shown here, although 11 would not be apparent

in the actual field installation

Figure 5-45. Plotting board or graph paper plot showing optimum two-element move.

Several variations on the foregoing example are worth noting, and are

shown in Figure 5-46. The basic approach is the same for all though, and

is easy to apply once the principle is understood.

We have, to this point, made no mention of thermal growth. If this is to

be considered, the growth data may be superimposed on the basic mis-

alignment plots, or included prior to plotting, before proceeding with the

optimum-move solution. Also, of course, there are valid nongraphical

methods of handling the alignment solutions shown here-but we find the

graphical approach easier for visualization, and accurate enough if done

carefully.