Page 311 - Machinery Component Maintenance

P. 311

Balancing of Machinery Components 293

be sufficient if the rotor fell within the bottom 20 percent of the ma-

chine weight range. For hard-bearing machines, it is not as important to

test the lower end of the weight range, since parasitic mass has little ef-

fect on the readout sensitivity of such machines.

Testing both soft- or hard-bearing machines in the upper 20 percent of

their weight range will verify their weight carrying and drive capability,

but add little additional knowledge concerning the measuring system. On

machines with weight ranges larger than 10,OOO lbs it may be impractical

to call for a test near the upper weight limit before shipment, since a bal-

ancing machine manufacturer rarely has such heavy rotors on hand. A

final test after installation with an actual rotor may then be the better

choice. In any case, it will generally suffice to include one small, or on

hard-bearing machines, one small to medium size proving rotor, in the

purchase of a machine. Rotors weighing several thousand pounds might

possibly be furnished temporarily by the balancing machine manufac-

turer for the acceptance test.

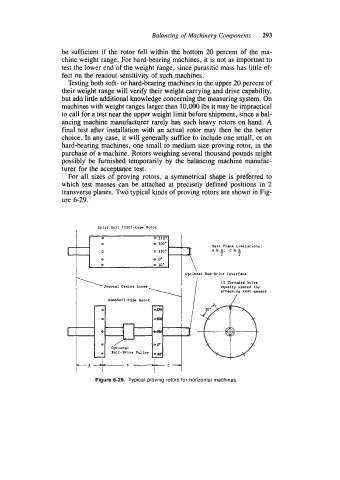

For all sizes of proving rotors, a symmetrical shape is preferred to

which test masses can be attached at precisely defined positions in 2

transverse planes. Two typical kinds of proving rotors are shown in Fig-

ure 6-29.

Solid Roll (ISO)-type Rotor

270.

0 300.

Test Plane Limitations:

0 330. brl; c=B

2 2

0 30'

Optional End-Drive Interface

I2 Threaded holes

Journal Center Lines equally spaced for

attaching test masses

Dumbbell-type Rotor

t-A~B--tc-i

Figure 6-29. Typical proving rotors for horizontal machines.