Page 179 - Make Your Own PCBs with EAGLE from Schematic Designs to Finished Boards

P. 179

FIGURE 7-9 Nonmagnetic tweezers.

The tweezers should have a fine point and, most important, be nonmagnetic. If they are even

slightly magnetic, then SMDs will stick to them because many contain ferrous metals.

Magnifier

It can be really hard to see what you are doing when you are working with surface-mount technology

(SMT). A large magnifying work lamp such as that shown in Figure 7-10 can be a great help.

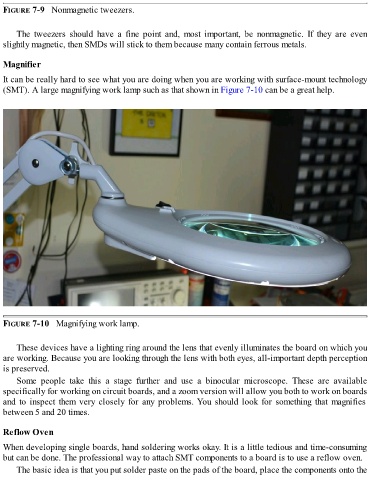

FIGURE 7-10 Magnifying work lamp.

These devices have a lighting ring around the lens that evenly illuminates the board on which you

are working. Because you are looking through the lens with both eyes, all-important depth perception

is preserved.

Some people take this a stage further and use a binocular microscope. These are available

specifically for working on circuit boards, and a zoom version will allow you both to work on boards

and to inspect them very closely for any problems. You should look for something that magnifies

between 5 and 20 times.

Reflow Oven

When developing single boards, hand soldering works okay. It is a little tedious and time-consuming

but can be done. The professional way to attach SMT components to a board is to use a reflow oven.

The basic idea is that you put solder paste on the pads of the board, place the components onto the