Page 659 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 659

Chapter 23 Machining Processes: Turning and Hole Making

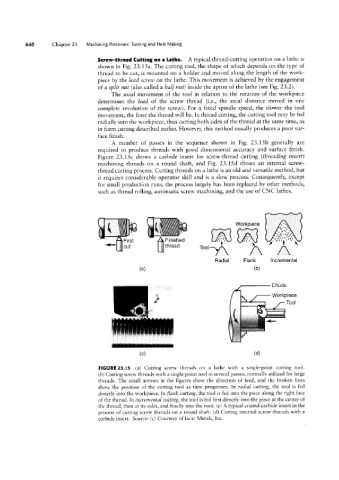

Screw-thread Cutting on a Lathe. A typical thread-cutting operation on a lathe is

shown in Fig. 23.15a. The cutting tool, the shape of which depends on the type of

thread to be cut, is mounted on a holder and moved along the length of the work-

piece by the lead screw on the lathe. This movement is achieved by the engagement

of a split nut (also called a laalf nut) inside the apron of the lathe (see Fig. 232).

The axial movement of the tool in relation to the rotation of the workpiece

determines the lead of the screw thread (i.e., the axial distance moved in one

complete revolution of the screw). For a fixed spindle speed, the slower the tool

movement, the finer the thread will be. ln thread cutting, the cutting tool may be fed

radially into the workpiece, thus cutting both sides of the thread at the same time, as

in form cutting described earlier. However, this method usually produces a poor sur-

face finish.

A number of passes in the sequence shown in Fig. 23.15b generally are

required to produce threads with good dimensional accuracy and surface finish.

Figure 23.15c shows a carbide insert for screw-thread cutting (threading insert)

machining threads on a round shaft, and Fig. 23.15d shows an internal screw-

thread cutting process. Cutting threads on a lathe is an old and versatile method, but

it requires considerable operator skill and is a slow process. Consequently, except

for small production runs, the process largely has been replaced by other methods,

such as thread rolling, automatic screw machining, and the use of CNC lathes.

\ ToO|Y\

/:

§ 7 //l;§\. /////f i `\/Y/l¥\\‘./\

\\>;;`::{\’/

/ 1

‘_ cut thread y.

Fladial Flank Incremental

(H) (bl

Chuck

Workpiece

Tool

(C) (dl

FIGURE 23.15 la) Cutting screw threads on a lathe with a single-point cutting tool.

(b) Cutting screw threads with a single-point tool in several passes, normally utilized for large

threads. The small arrows in the figures show the direction of feed, and the broken lines

show the position of the cutting tool as time progresses. In radial cutting, the tool is fed

directly into the workpiece. In flank cutting, the tool is fed into the piece along the right face

of the thread. In incremental cutting, the tool is fed first directly into the piece at the center of

the thread, then at its sides, and finally into the root. (c) A typical coated-carbide insert in the

process of cutting screw threads on a round shaft. (d) Cutting internal screw threads with a

carbide insert. Source: (c) Courtesy of Iscar Metals, Inc.