Page 660 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 660

workpiece

Boring and Boring Machmes

Section 23.4

Workpiece Die

A

r

G

\

V

._

QE

RE, .';.:;i»=:; <07

O

Circular Chaser . ,, ’

Cutting edge

Cutting edge

(H) (D) (C)

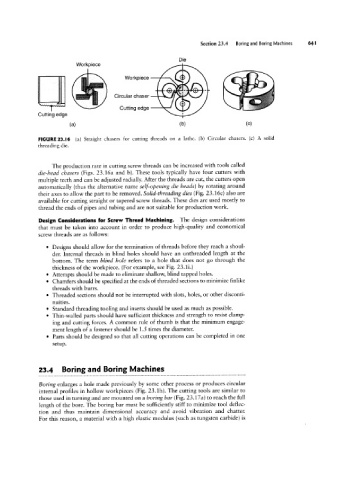

FIGURE 23.16 (a) Straight chasers for cutting threads on a lathe. (b) Circular chasers. (c) A solid

threading die.

The production rate in cutting screw threads can be increased with tools called

die-head chasers (Figs. 23.16a and b). These tools typically have four cutters with

multiple teeth and can be adjusted radially. After the threads are cut, the cutters open

automatically (thus the alternative name self-opening die heads) by rotating around

their axes to allow the part to be removed. Solid-threading dies (Fig. 23.16c) also are

available for cutting straight or tapered screw threads. These dies are used mostly to

thread the ends of pipes and tubing and are not suitable for production work.

Design Considerations for Screw Thread Machining. The design considerations

that must be taken into account in order to produce high-quality and economical

screw threads are as follows:

° Designs should allow for the termination of threads before they reach a shoul-

der. Internal threads in blind holes should have an unthreaded length at the

bottom. The term blind hole refers to a hole that does not go through the

thickness of the workpiece. (For example, see Fig. 23.1i.)

° Attempts should be made to eliminate shallow, blind tapped holes.

° Chamfers should be specified at the ends of threaded sections to minimize finlike

threads with burrs.

° Threaded sections should not be interrupted with slots, holes, or other disconti-

nuities.

° Standard threading tooling and inserts should be used as much as possible.

° Thin-walled parts should have sufficient thickness and strength to resist clamp-

ing and cutting forces. A common rule of thumb is that the minimum engage-

ment length of a fastener should be 1.5 times the diameter.

° Parts should be designed so that all cutting operations can be completed in one

setup.

23.4 Boring and Boring Machines

Boring enlarges a hole made previously by some other process or produces circular

internal profiles in hollow workpieces (Fig. 23.1h). The cutting tools are similar to

those used in turning and are mounted on a boring har (Fig. 23.1721) to reach the full

length of the bore. The boring bar must be sufficiently stiff to minimize tool deflec-

tion and thus maintain dimensional accuracy and avoid vibration and chatter.

For this reason, a material with a high elastic modulus (such as tungsten carbide) is