Page 665 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 665

Chapter 23 Machining Processes: Turning and Hole Making

Outer point

*angle Margin Tl it Cutting-fluid

2 _' 13 Wear pads

fQ,f fQ f j§ ff§ ‘

;;¢;::;1)

Spindka (H) Drill

lnner point

angle

Cutting-fluid

I

Rotating cutting-fluid feed line

transfer gland

Drill 4- Feed Workpiece

B

(D)

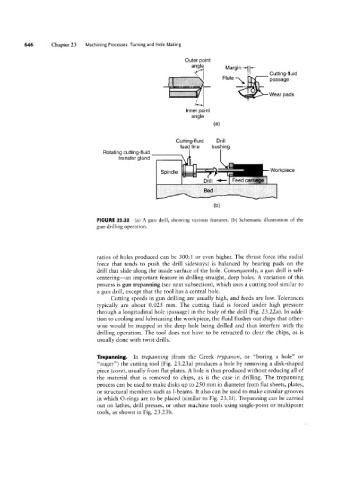

FIGURE 23.22 (a) A gun drill, showing various features. (b) Schematic illustration of the

gun-drilling operation.

ratios of holes produced can be 300:1 or even higher. The thrust force (the radial

force that tends to push the drill sideways) is balanced by bearing pads on the

drill that slide along the inside surface of the hole. Consequently, a gun drill is self-

centering-an important feature in drilling straight, deep holes. A variation of this

process is gun trepanning (see next subsection), which uses a cutting tool similar to

a gun drill, except that the tool has a central hole.

Cutting speeds in gun drilling are usually high, and feeds are low. Tolerances

typically are about 0.025 mm. The cutting fluid is forced under high pressure

through a longitudinal hole (passage) in the body of the drill (Fig. 23.22a). In addi-

tion to cooling and lubricating the workpiece, the fluid flushes out chips that other-

wise would be trapped in the deep hole being drilled and thus interfere with the

drilling operation. The tool does not have to be retracted to clear the chips, as is

usually done with twist drills.

Trepanning. In trepanning (from the Greek trypanon, or “boring a hole” or

“auger”) the cutting tool (Fig. 23.23a) produces a hole by removing a disk-shaped

piece (core), usually from flat plates. A hole is thus produced without reducing all of

the material that is removed to chips, as is the case in drilling. The trepanning

process can be used to make disks up to 250 mm in diameter from flat sheets, plates,

or structural members such as I-beams. It also can be used to make circular grooves

in which O-rings are to be placed (similar to Fig. 23.1f). Trepanning can be carried

out on lathes, drill presses, or other machine tools using single-point or multipoint

tools, as shown in Fig. 23.23b.