Page 669 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 669

0 Chapter 23 Machining Processes: Turning and Hole Making

TABLE 23.l2

General Troubleshooting Guide for Drilling Operations

Problem Probable causes

Drill breakage Dull drill, drill seizing in hole because of chips clogging flutes,

feed too high, lip relief angle too small

Excessive drill wear Cutting speed too high, ineffective cutting fluid, rake angle too

high, drill burned and strength lost when drill was sharpened

Tapered hole Drill misaligned or bent, lips not equal, web not central

Oversize hole Same as previous entry, machine spindle loose, chisel edge not

central, side force on workpiece

Poor hole surface finish Dull drill, ineffective cutting fluid, welding of workpiece material

on drill margin, improperly ground drill, improper alignment

4' l Radial arm

Fixed head “gf j

(power head) "°fff t,», 13, ,,

"ff V - Hand wheel

Spindle ’“”C°|Um" Q9

Adjustablehead

/

Hand wheel '_ Chuck

Chuck

Base _ Table

Spindle 3

f

Table V _

(3) (D)

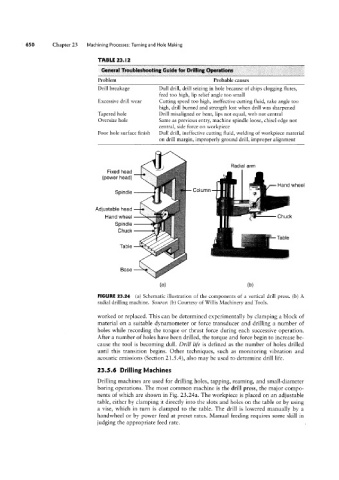

FIGURE 23.24 (a) Schematic illustration of the components of a vertical drill press. (b) A

radial drilling machine. Source: (b) Courtesy of Willis Machinery and Tools.

worked or replaced. This can be determined experimentally by clamping a block of

material on a suitable dynamometer or force transducer and drilling a number of

holes while recording the torque or thrust force during each successive operation.

After a number of holes have been drilled, the torque and force begin to increase be-

cause the tool is becoming dull. Drill life is defined as the number of holes drilled

until this transition begins. Other techniques, such as monitoring vibration and

acoustic emissions (Section 21.5.4), also may be used to determine drill life.

23.5.6 Drilling Machines

Drilling machines are used for drilling holes, tapping, reaming, and small-diameter

boring operations. The most common machine is the drill press, the major compo-

nents of which are shown in Fig. 23.24a. The workpiece is placed on an adjustable

table, either by clamping it directly into the slots and holes on the table or by using

a vise, which in turn is clamped to the table. The drill is lowered manually by a

handwheel or by power feed at preset rates. Manual feeding requires some skill in

judging the appropriate feed rate.