Page 672 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 672

Section 23 .7 Tapping and Taps

Shell reamers (which are hollow and are mounted on an arbor) generally are

used for holes larger than 20 mm. Expansion reamers are adjustable for small vari-

ations in hole size and also to compensate for wear of the reamer’s cutting edges.

Adjustable reamers (Fig. 23.26b) can be set for specific hole diameters and therefore

are versatile.

Reamers may be held rigidly (as in a chuck), or they may float in their holding

fixtures to ensure alignment or be piloted in guide bushings placed above and below

the workpiece. A further development in reaming consists of the dreamer-a tool

that combines drilling and reaming. The tip of the tool produces a hole by drilling,

and the rest of the same tool performs a reaming operation. A similar development

involves drilling and tapping in one stroke, using a single tool.

Reamers typically are made of high-speed steels (Ml, MZ, and M7) or solid

carbides (K2O; C2), or have carbide cutting edges. Reamer maintenance and recon-

ditioning are important for hole accuracy and surface finish.

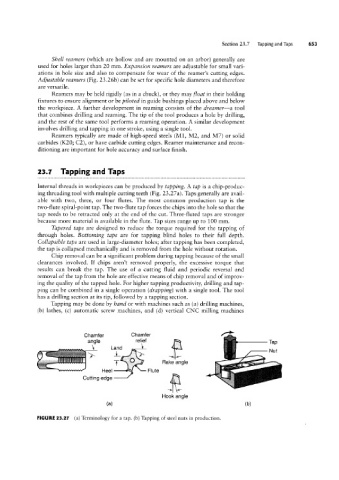

23.7 Tapping and Taps

Internal threads in workpieces can be produced by tapping. A tap is a chip-produc-

ing threading tool with multiple cutting teeth (Fig. 23.27a). Taps generally are avail-

able with two, three, or four flutes. The most common production tap is the

two-flute spiral-point tap. The two-flute tap forces the chips into the hole so that the

tap needs to be retracted only at the end of the cut. Three-fluted taps are stronger

because more material is available in the flute. Tap sizes range up to 100 mm.

Tapered taps are designed to reduce the torque required for the tapping of

through holes. Bottoming taps are for tapping blind holes to their full depth.

Collapsible taps are used in large-diameter holes; after tapping has been completed,

the tap is collapsed mechanically and is removed from the hole without rotation.

Chip removal can be a significant problem during tapping because of the small

clearances involved. If chips aren’t removed properly, the excessive torque that

results can break the tap. The use of a cutting fluid and periodic reversal and

removal of the tap from the hole are effective means of chip removal and of improv-

ing the quality of the tapped hole. For higher tapping productivity, drilling and tap-

ping can be combined in a single operation (drapping) with a single tool. The tool

has a drilling section at its tip, followed by a tapping section.

Tapping may be done by hand or with machines such as (a) drilling machines,

T

(b) lathes, (C) automatic screw machines, and (d) vertical CNC milling machines

Chamfer

Cllamfel’

relief

;_

.

Nut

_,,_

. lliillellsiiliiaslllli angle Land J- Rake angle Tap

Heel Flute

Cutting edge

Hook angle

(3) (D)

FIGURE 23.27 (a) Terminology for a tap. (b) Tapping of steel nuts in production.