Page 666 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 666

.aw Spindle Section 23.5 E Drilling, Drills and Drilling Machines

Y'§`t€

J

Q

Shank

E5

Tool

gi

Cutting tools J, . . Workpiece 0

Drill lrv. Q

(H) ' ` (D)

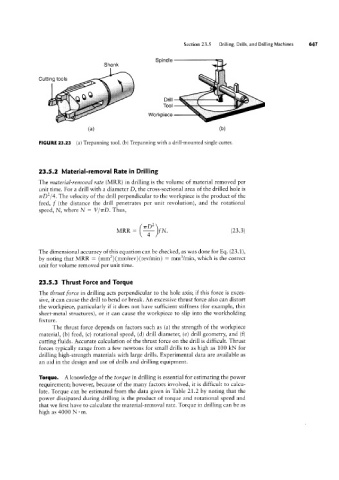

FIGURE 23.23 (a) Trepanning tool. (bl Trepanning with a drill-mounted single cutter.

23.5.2 Material-removal Rate in Drilling

The material-removal rate (MRR) in drilling is the volume of material removed per

unit time. For a drill with a diameter D, the cross-sectional area of the drilled hole is

1-rD2/4. The velocity of the drill perpendicular to the workpiece is the product of the

feed, f (the distance the drill penetrates per unit revolution), and the rotational

speed, N, where N = V/WD. Thus,

MRR = (#>fN. (23.3)

The dimensional accuracy of this equation can be checked, as was done for Eq. (23.1 ),

by noting that MRR = (mm2)(mm/rev)(rev/min) = mm3/min, which is the correct

unit for volume removed per unit time.

23.5.3 Thrust Force and Torque

The thrust force in drilling acts perpendicular to the hole axis; if this force is exces-

sive, it can cause the drill to bend or break. An excessive thrust force also can distort

the workpiece, particularly if it does not have sufficient stiffness (for example, thin

sheet-metal structures), or it can Cause the workpiece to slip into the workholding

fixture.

The thrust force depends on factors such as (a) the strength of the workpiece

material, (b) feed, (c) rotational speed, (d) drill diameter, (el drill geometry, and (f)

cutting fluids. Accurate calculation of the thrust force on the drill is difficult. Thrust

forces typically range from a few newtons for small drills to as high as 100 kN for

drilling high-strength materials with large drills. Experimental data are available as

an aid in the design and use of drills and drilling equipment.

Torque. A knowledge of the torque in drilling is essential for estimating the power

requirement; however, because of the many factors involved, it is difficult to calcu-

late. Torque can be estimated from the data given in Table 21.2 by noting that the

power dissipated during drilling is the product of torque and rotational speed and

that we first have to calculate the material-removal rate. Torque in drilling can be as

high as 4000 N m.

°