Page 398 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 398

378 Chapter 15 Metal Extrusion and Drawing Processes and Equipment

Drum-speed

control lever

/- Drum

I

Lubricant container

with holder for dies

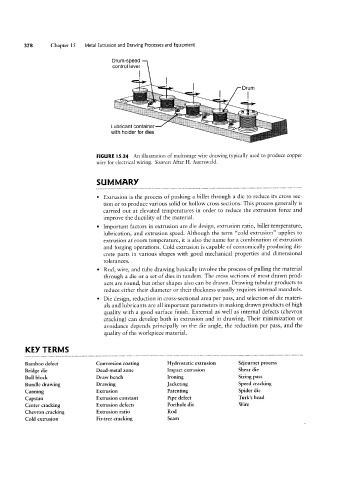

FIGURE l5.24 An illustration of multistage wire drawing typically used to produce copper

wire for electrical wiring. Source: After H. Auerswald.

SUMMARY

Extrusion is the process of pushing a billet through a die to reduce its cross sec-

tion or to produce various solid or hollow cross sections. This process generally is

carried out at elevated temperatures in order to reduce the extrusion force and

improve the ductility of the material.

Important factors in extrusion are die design, extrusion ratio, billet temperature,

lubrication, and extrusion speed. Although the term “cold extrusion” applies to

extrusion at room temperature, it is also the name for a combination of extrusion

and forging operations. Cold extrusion is capable of economically producing dis-

crete parts in various shapes with good mechanical properties and dimensional

tolerances.

Rod, wire, and tube drawing basically involve the process of pulling the material

through a die or a set of dies in tandem. The cross sections of most drawn prod-

ucts are round, but other shapes also can be drawn. Drawing tubular products to

reduce either their diameter or their thickness usually requires internal mandrels.

Die design, reduction in cross-sectional area per pass, and selection of die materi-

als and lubricants are all important parameters in making drawn products of high

quality with a good surface finish. External as Well as internal defects (chevron

cracking) can develop both in extrusion and in drawing. Their minimization or

avoidance depends principally on the die angle, the reduction per pass, and the

quality of the workpiece material.

KEY TERMS

Bamboo defect Conversion coating Hydrostatic extrusion Séjournet process

Bridge die Dead-metal zone Impact extrusion Shear die

Bull block Draw bench Ironing Sizing pass

Bundle drawing Drawing _lacketing Speed cracking

Canning Extrusion Patenting Spider die

Capstan Extrusion constant Pipe defect Turk’s head

Center cracking Extrusion defects Porthole die Wire

Chevron cracking Extrusion ratio Rod

Cold extrusion Fir-tree cracking Seam