Page 636 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 636

Section 23.1 lntroduction

TABLE 23.l

General Characteristics of Machining Processes and Typical Dimensional Tolerances

Typical dimensional

Process Characteristics tolerances, :t mm

Turning Turning and facing operations on all types of materials, uses Fine: 0.025-0.13

single-point or form tools; engine lathes require skilled labor; low Rough: 0.13

production rate (but medium-to-high rate with turret lathes and

automatic machines) requiring less skilled labor

Boring Internal surfaces or profiles with characteristics similar to turning; 0.025

stiffness of boring bar important to avoid chatter

Drilling Round holes of various sizes and depths; high production rate; labor 0.075

skill required depends on hole location and accuracy specified; requires

boring and reaming for improved accuracy

Milling Wide variety of shapes involving contours, flat surfaces, and slots; 0.013-0.025

versatile; low-to-medium production rate; requires skilled labor

Planing Large flat surfaces and straight contour profiles on long Workpieces, 0.08-0.13

low-quantity production, labor skill required depends on part shape

Shaping Flat surfaces and straight contour profiles on relatively small Workpieces; 0.05-0.08

low-quantity production; labor skill required depends on part shape

Broaching External and internal surfaces, slots, and contours; good surface finish; 0.025-0.15

costly tooling; high production rate; labor skill required depends on

part shape

Sawing Straight and contour cuts on flat or structural shapes; not suitable for 0.8

hard materials unless saw has carbide teeth or is coated with diamond;

low production rate; generally low labor skill

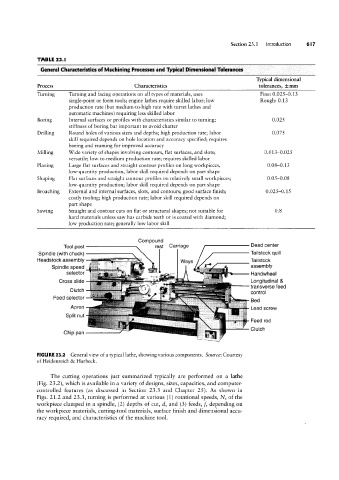

Compound

Tool post rest Carriage Dead Center

Spindle (with chuck) Tailstock quill

Headstock assembly YS Tailstock

Spindle speed assembly

Selector M Handwheel

Cross slide Longitudinal &

transverse feed

Clutch

control

Feed selector

Bed

Apron Lead screw

Split nut

Feed rod

Clutch

Chip pan

FIGURE 23.2 General view of a typical lathe, showing various components. Source: Courtesy

of Heidenreich 86 Harbeck.

The cutting operations just summarized typically are performed on a lathe

(Fig. 23.2), which is available in a variety of designs, sizes, capacities, and computer~

controlled features (as discussed in Section 23.3 and Chapter 25). As shown in

Figs. 21.2 and 23.3, turning is performed at various (1) rotational speeds, N, of the

workpiece clamped in a spindle, (2) depths of cut, d, and (3) feeds, 12 depending on

the workpiece materials, cutting-tool materials, surface finish and dimensional accu-

racy required, and characteristics of the machine tool.