Page 366 - Marks Calculation for Machine Design

P. 366

P1: Sanjay

January 4, 2005

Brown˙C08

Brown.cls

348

U.S. Customary 15:14 APPLICATION TO MACHINES SI/Metric

Summarizing, Summarizing,

n load = 1.78 < 2 n load = 1.87 < 2

n separation = 5.9 ∼ 6 n separation = 6.5

=

n fatigue = 2.4 n fatigue = 2.4

n yield = 1.13 n yield = 1.15

Only the factor-of-safety against yielding Only the factor-of-safety against yielding

(n yield ) should be of concern. (n yield ) should be of concern.

8.3 WELDED CONNECTIONS

Again, as the overall theme of this book is to uncover the mystery of the formulas used

in machine design for the practicing engineer, it will be assumed that the details of the

nomenclature of welds and the standards of the American Welding Society (AWS) are

unnecessary. Therefore the discussion will proceed directly to the first important topic for

the designer, welded joints in axial and transverse loading.

8.3.1 Axial and Transverse Loading

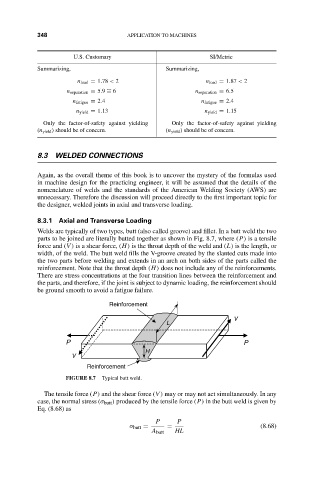

Welds are typically of two types, butt (also called groove) and fillet. In a butt weld the two

parts to be joined are literally butted together as shown in Fig. 8.7, where (P) is a tensile

force and (V ) is a shear force, (H) is the throat depth of the weld and (L) is the length, or

width, of the weld. The butt weld fills the V-groove created by the slanted cuts made into

the two parts before welding and extends in an arch on both sides of the parts called the

reinforcement. Note that the throat depth (H) does not include any of the reinforcements.

There are stress concentrations at the four transition lines between the reinforcement and

the parts, and therefore, if the joint is subject to dynamic loading, the reinforcement should

be ground smooth to avoid a fatigue failure.

Reinforcement

V

L

P P

H

V

Reinforcement

FIGURE 8.7 Typical butt weld.

The tensile force (P) and the shear force (V ) may or may not act simultaneously. In any

case, the normal stress (σ butt ) produced by the tensile force (P) in the butt weld is given by

Eq. (8.68) as

P P

σ butt = = (8.68)

A butt HL