Page 369 - Marks Calculation for Machine Design

P. 369

P1: Sanjay

15:14

January 4, 2005

Brown˙C08

Brown.cls

L

H MACHINE ASSEMBLY 351

t

P

P

Edge view Side view

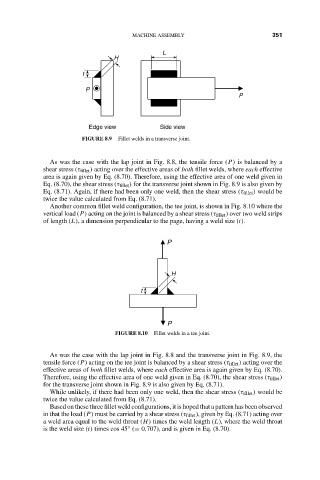

FIGURE 8.9 Fillet welds in a transverse joint.

As was the case with the lap joint in Fig. 8.8, the tensile force (P) is balanced by a

shear stress (τ fillet ) acting over the effective areas of both fillet welds, where each effective

area is again given by Eq. (8.70). Therefore, using the effective area of one weld given in

Eq. (8.70), the shear stress (τ fillet ) for the transverse joint shown in Fig. 8.9 is also given by

Eq. (8.71). Again, if there had been only one weld, then the shear stress (τ fillet ) would be

twice the value calculated from Eq. (8.71).

Another common fillet weld configuration, the tee joint, is shown in Fig. 8.10 where the

vertical load (P) acting on the joint is balanced by a shear stress (τ fillet ) over two weld strips

of length (L), a dimension perpendicular to the page, having a weld size (t).

P

H

t

P

FIGURE 8.10 Fillet welds in a tee joint.

As was the case with the lap joint in Fig. 8.8 and the transverse joint in Fig. 8.9, the

tensile force (P) acting on the tee joint is balanced by a shear stress (τ fillet ) acting over the

effective areas of both fillet welds, where each effective area is again given by Eq. (8.70).

Therefore, using the effective area of one weld given in Eq. (8.70), the shear stress (τ fillet )

for the transverse joint shown in Fig. 8.9 is also given by Eq. (8.71).

While unlikely, if there had been only one weld, then the shear stress (τ fillet ) would be

twice the value calculated from Eq. (8.71).

Based on these three fillet weld configurations, it is hoped that a pattern has been observed

in that the load (P) must be carried by a shear stress (τ fillet ), given by Eq. (8.71) acting over

a weld area equal to the weld throat (H) times the weld length (L), where the weld throat

is the weld size (t) times cos 45 (= 0.707), and is given in Eq. (8.70).

◦