Page 429 - Marks Calculation for Machine Design

P. 429

P2: Sanjay

P1: Shibu/Rakesh

January 4, 2005

15:34

Brown.cls

Brown˙C10

MACHINE MOTION

Arm

2

2 Arm 411

Crank Crank

1 1

Input C Input C

A 3 A 3

Sliding block

Collar

Output Output

B B

(a) (b)

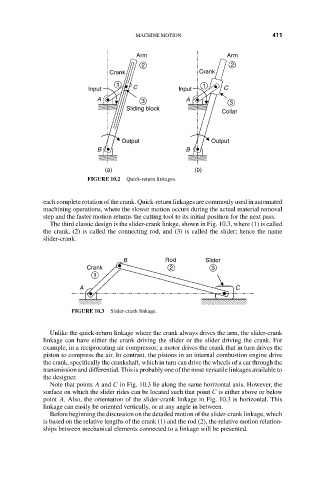

FIGURE 10.2 Quick-return linkages.

each complete rotation of the crank. Quick-return linkages are commonly used in automated

machining operations, where the slower motion occurs during the actual material removal

step and the faster motion returns the cutting tool to its initial position for the next pass.

The third classic design is the slider-crank linkge, shown in Fig. 10.3, where (1) is called

the crank, (2) is called the connecting rod, and (3) is called the slider; hence the name

slider-crank.

B Rod Slider

Crank 2 3

1

A C

FIGURE 10.3 Slider-crank linkage.

Unlike the quick-return linkage where the crank always drives the arm, the slider-crank

linkage can have either the crank driving the slider or the slider driving the crank. For

example, in a reciprocating air compressor, a motor drives the crank that in turn drives the

piston to compress the air. In contrast, the pistons in an internal combustion engine drive

the crank, specifically the crankshaft, which in turn can drive the wheels of a car through the

transmission and differential. This is probably one of the most versatile linkages available to

the designer.

Note that points A and C in Fig. 10.3 lie along the same horizontal axis. However, the

surface on which the slider rides can be located such that point C is either above or below

point A. Also, the orientation of the slider-crank linkage in Fig. 10.3 is horizontal. This

linkage can easily be oriented vertically, or at any angle in between.

Before beginning the discussion on the detailed motion of the slider-crank linkage, which

is based on the relative lengths of the crank (1) and the rod (2), the relative motion relation-

ships between mechanical elements connected to a linkage will be presented.