Page 200 - Materials Science and Engineering An Introduction

P. 200

172 • Chapter 6 / Mechanical Properties of Metals

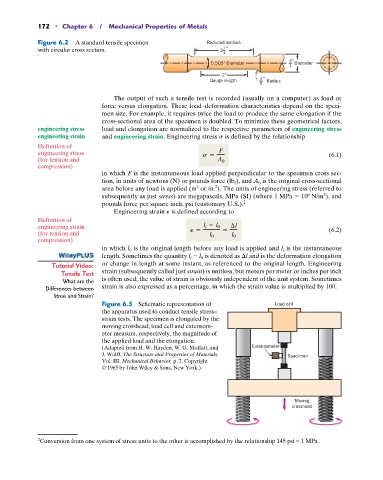

Figure 6.2 A standard tensile specimen Reduced section

with circular cross section. 2 "

1

4

3 "

"

0.505 Diameter Diameter

4

2"

Gauge length 3 " Radius

8

The output of such a tensile test is recorded (usually on a computer) as load or

force versus elongation. These load–deformation characteristics depend on the speci-

men size. For example, it requires twice the load to produce the same elongation if the

cross-sectional area of the specimen is doubled. To minimize these geometrical factors,

engineering stress load and elongation are normalized to the respective parameters of engineering stress

engineering strain and engineering strain. Engineering stress s is defined by the relationship

Definition of

engineering stress s = F (6.1)

(for tension and A 0

compression)

in which F is the instantaneous load applied perpendicular to the specimen cross sec-

tion, in units of newtons (N) or pounds force (lb f ), and A 0 is the original cross-sectional

2

2

area before any load is applied (m or in. ). The units of engineering stress (referred to

6

2

subsequently as just stress) are megapascals, MPa (SI) (where 1 MPa 10 N/m ), and

pounds force per square inch, psi (customary U.S.). 2

Engineering strain P is defined according to

Definition of

engineering strain l i - l 0 l (6.2)

(for tension and P = l 0 = l 0

compression)

in which l 0 is the original length before any load is applied and l i is the instantaneous

length. Sometimes the quantity l i l 0 is denoted as l and is the deformation elongation

Tutorial Video: or change in length at some instant, as referenced to the original length. Engineering

Tensile Test strain (subsequently called just strain) is unitless, but meters per meter or inches per inch

What are the is often used; the value of strain is obviously independent of the unit system. Sometimes

Differences between strain is also expressed as a percentage, in which the strain value is multiplied by 100.

Stress and Strain?

Figure 6.3 Schematic representation of Load cell

the apparatus used to conduct tensile stress–

strain tests. The specimen is elongated by the

moving crosshead; load cell and extensom-

eter measure, respectively, the magnitude of

the applied load and the elongation.

(Adapted from H. W. Hayden, W. G. Moffatt, and Extensometer

J. Wulff, The Structure and Properties of Materials, Specimen

Vol. III, Mechanical Behavior, p. 2. Copyright

© 1965 by John Wiley & Sons, New York.)

Moving

crosshead

2 Conversion from one system of stress units to the other is accomplished by the relationship 145 psi = 1 MPa.