Page 216 - Materials Science and Engineering An Introduction

P. 216

188 • Chapter 6 / Mechanical Properties of Metals

true strain Furthermore, it is occasionally more convenient to represent strain as true strain P T ,

defined by

Definition of true P T = ln l i (6.16)

strain l 0

If no volume change occurs during deformation—that is, if

A i l i = A 0 l 0 (6.17)

—then true and engineering stress and strain are related according to

Conversion of

engineering stress s T = s(1 + P) (6.18a)

to true stress

Conversion of (6.18b)

engineering strain P T = ln (1 + P)

to true strain

Equations 6.18a and 6.18b are valid only to the onset of necking; beyond this point, true

stress and strain should be computed from actual load, cross-sectional area, and gauge

length measurements.

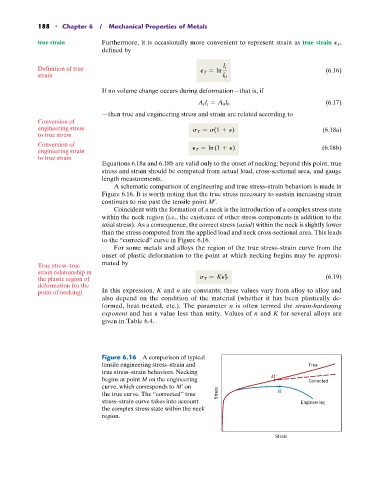

A schematic comparison of engineering and true stress–strain behaviors is made in

Figure 6.16. It is worth noting that the true stress necessary to sustain increasing strain

continues to rise past the tensile point M¿.

Coincident with the formation of a neck is the introduction of a complex stress state

within the neck region (i.e., the existence of other stress components in addition to the

axial stress). As a consequence, the correct stress (axial) within the neck is slightly lower

than the stress computed from the applied load and neck cross-sectional area. This leads

to the “corrected” curve in Figure 6.16.

For some metals and alloys the region of the true stress–strain curve from the

onset of plastic deformation to the point at which necking begins may be approxi-

True stress–true mated by

strain relationship in n

the plastic region of s T = KP T (6.19)

deformation (to the

point of necking) In this expression, K and n are constants; these values vary from alloy to alloy and

also depend on the condition of the material (whether it has been plastically de-

formed, heat-treated, etc.). The parameter n is often termed the strain-hardening

exponent and has a value less than unity. Values of n and K for several alloys are

given in Table 6.4.

Figure 6.16 A comparison of typical

tensile engineering stress–strain and True

true stress–strain behaviors. Necking

begins at point M on the engineering M Corrected

curve, which corresponds to M¿ on

the true curve. The “corrected” true Stress M

stress–strain curve takes into account Engineering

the complex stress state within the neck

region.

Strain