Page 295 - Materials Science and Engineering An Introduction

P. 295

8.6 Fracture Toughness Testing • 267

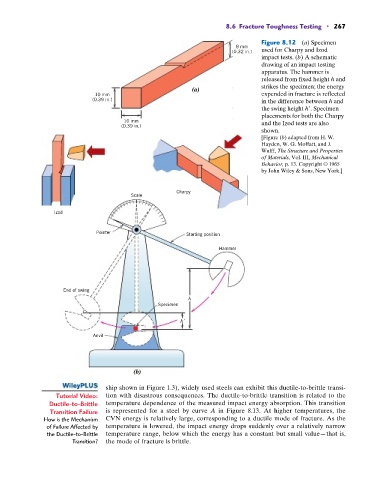

Figure 8.12 (a) Specimen

8 mm

(0.32 in.) used for Charpy and Izod

impact tests. (b) A schematic

drawing of an impact testing

apparatus. The hammer is

released from fixed height h and

strikes the specimen; the energy

(a)

10 mm expended in fracture is reflected

(0.39 in.) in the difference between h and

the swing height h . Specimen

placements for both the Charpy

10 mm and the Izod tests are also

(0.39 in.)

shown.

[Figure (b) adapted from H. W.

Hayden, W. G. Moffatt, and J.

Wulff, The Structure and Properties

of Materials, Vol. III, Mechanical

Behavior, p. 13. Copyright © 1965

by John Wiley & Sons, New York.]

Charpy

Scale

Izod

Pointer Starting position

Hammer

End of swing

h

Specimen

h'

Anvil

(b)

ship shown in Figure 1.3), widely used steels can exhibit this ductile-to-brittle transi-

Tutorial Video: tion with disastrous consequences. The ductile-to-brittle transition is related to the

Ductile-to-Brittle temperature dependence of the measured impact energy absorption. This transition

Transition Failure is represented for a steel by curve A in Figure 8.13. At higher temperatures, the

How is the Mechanism CVN energy is relatively large, corresponding to a ductile mode of fracture. As the

of Failure Affected by temperature is lowered, the impact energy drops suddenly over a relatively narrow

the Ductile-to-Brittle temperature range, below which the energy has a constant but small value—that is,

Transition? the mode of fracture is brittle.