Page 144 - Materials Chemistry, Second Edition

P. 144

131

2.4. The Amorphous State

borosilicate glass. The physical properties of this glass resemble fused silica (e.g.,

1

coefficient of thermal expansion: 3.3 10 7 cm cm 1 K ), except that its soften-

ing temperature is only ca. 700 C. Borosilicate glass is the variety that is sold in

™

stores as Pyrex cookware and laboratory equipment. These applications demand a

glass that resists thermal expansion (i.e., cracking) as a result of significant changes

in temperature.

It was not until the late seventeenth century that PbO was substituted for lime in glass

formulations. This “soda–lead” glass is what we know as crystal (referred to as flint

glass in pre-Civil War America), and has always been a symbol of wealth and

extravagance such as expensive glassware and chandeliers. In order for crystal to be

legally given the “full lead” designation, at least 24% of lead oxide must be present in

its structure. The addition of the heavy element lead adds significant weight to the glass,

while increasing its refractive index. This latter property results in the familiar clear,

sparkling appearance of crystal glassware. The presence of lead also makes the glass

softer than regular types that must be cut with a diamond saw. Black crystal is truly one

of the most fabulous materials for modern artistic design. The lack of transparency is

caused by a combination of additives – typically Fe 2 O 3 ,CuO,MnO 2 ,and Co 2 O 3 .

Colored glass has been used since the construction of the first churches, prior to

the tenth century. Although decorative applications represent the majority of uses

for colored glass, there are some other recent functional applications such as traffic

light signals. The colors imparted by glass are a result of dopant species that are

added during its fabrication (Table 2.13). Both transition metal ions and colloidal

suspensions yield an observable color, with the hue dependent on the concentration

used. Variation of the color and intensity is also extremely sensitive toward the

heating regime (both temperatures and exposure times) used during the glassmaking

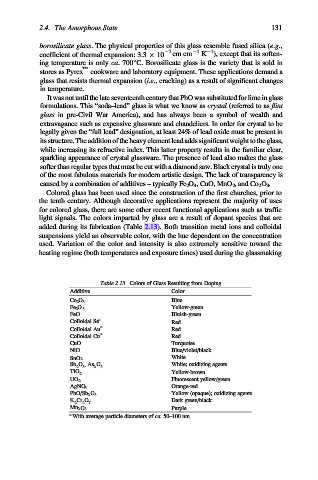

Table 2.13. Colors of Glass Resulting from Doping

Additive Color

Blue

Co 2 O 3

Yellow-green

Fe 2 O 3

FeO Bluish-green

Colloidal Se a Red

Colloidal Au a Red

Colloidal Cu a Red

CuO Turquoise

NiO Blue/violet/black

SnO 2 White

Sb 2 O 3 ,As 2 O 3 White; oxidizing agents

TiO 2 Yellow-brown

UO 2 Fluorescent yellow/green

Orange-red

AgNO 3

Yellow (opaque); oxidizing agents

PbO/Sb 2 O 3

Dark green/black

K 2 Cr 2 O 7

Purple

Mn 2 O 3

a

With average particle diameters of ca. 50–100 nm.