Page 132 - Mechanical Engineer's Data Handbook

P. 132

THERMODYNAMICS AND HEAT TRANSFER 121

I

Coding

water jacket-.

Cooling water-

jackel Combustion

zmiw-I - Push md

chamber

Piston-

Cylinder -

Crank angle, e

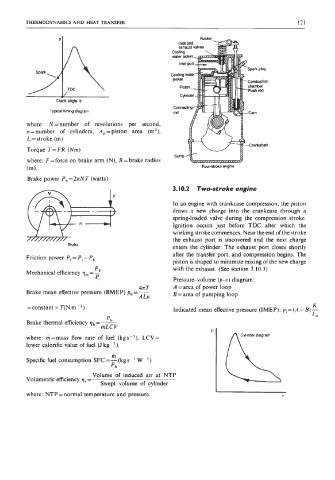

Typical timing diagram

where: N =number of revolutions per second,

n =number of cylinders, A, =piston area (m'),

L = stroke (m)

Torque T=FR (Nm)

Sump

where: F=force on brake arm (N), R= brake radius

(m). Four-stmke engine

Brake power Pb=2nNT (watts)

3.10.2 Two-stroke engine

In an engine with crankcase compression, the piston

draws a new charge into the crankcase through a

spring-loaded valve during the compression stroke.

Ignition occurs just before TDC after which the

working stroke commences. Near the end of the stroke

7f/m7n3r Brake the exhaust port is uncovered and the next charge

enters the cylinder. The exhaust port closes shortly

after the transfer port, and compression begins. The

Friction power P, = Pi - P,

piston is shaped to minimize mixing of the new charge

with the exhaust. (See section 3.10.3)

'

b

Mechanical efficiency )I,,, = -

Pi Pressure-volume (pu) diagram:

4n T A =area of power loop

Brake mean effective pressure (BMEP) pb=- B = area of pumping loop

ALn

=constant x T(N m ~ *) K

Indicated mean effective pressure (IMEP): pi = (A - B) -

L*

'b

Brake thermal efficiency 9 -~

,-mLCV

where: m=mass flow rate of fuel (kgs-I), LCV=

lower calorific value of fuel (J kg-').

m

Specific fuel consumption SFC =- (kg s- ' W- ')

Pb

Volume of induced air at NTP

Volumetric efficiency )I,, =

Swept volume of cylinder

where: NTP = normal temperature and pressure. V